Note: Our email addresses are only '[email protected]' '[email protected]' '[email protected]' Check the email addresses letter by letter to prevent scams

The ability to program complex tool paths and optimize cutting parameters enables manufacturers to achieve the highest standards of accuracy and surface finish. By using CNC lathe turning, companies can produce high-quality products that meet strict industry requirements and exceed customer expectations.

Efficiency is indispensable in the competitive industrial manufacturing of today. Automation is crucial to ensuring this efficiency, and CNC lathes are typical instances of such a pattern. By automating production processes, CNC lathes aid in manufacturing simplification, cost reduction and output increase.

Programming marks the beginning of automation for CNC lathes. Instead of laboriously programming each machine movement individually however, operators can quickly develop intricate tool paths with CAD/CAM software. The software then generates code required for controlling the lathe’s movements thereby considerably reducing time consumed and skill needed to program.

When tool paths have been programmed, these operations can be performed by a CNC lathe with unmatched precision. The computer controlled axes of the machine are highly accurate hence assuring that all parts are machined within their required dimensions. This leads to consistent production which will reduce scrap and rework thus saving on time and material costs.

CNC machine tools through automated programming allow precision machining multi-process integration not only enabling high-precision but also minimizing manual handling of dangerous tools or work pieces required from operators thereby reducing accidents risk and helping manufacturers achieve higher productivity as well as increased efficiency overall.

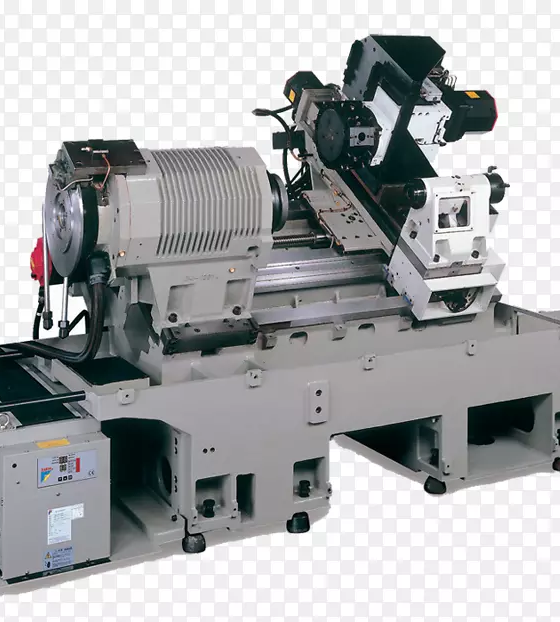

The world of manufacturing has seen a technological revolution through the use of CNC lathes. Manufacturers cannot do without them because they result in unmatched preciseness and consistency in the production of workpieces.

CNC lathe accuracy is achieved by performing highly precise machining operations. The machine has a computer control system that guides its movements with great exactness hence, no human error, constant results plus each and every workpiece is machined as required.

For optimal material removal rates and surface finish, these lathes employ precision tools designed for specific machining operations. There is also an automatic tool changer feature that changes tools as needed to reduce tool wear rate and maintain uniformity during machining over time.

To put it succinctly, the precision control systems on CNC lathes along with advanced cutting tools enhance the accuracy and consistency of work pieces. These machines become a reliable way for manufacturers to produce good quality work pieces to meet very high standards thus making them essential in modern day manufacturing.

Modern manufacturing depends on CNC Lathes which are very important tools in this process because they offer accuracy and efficiency in many different applications. Knowing the basics of how a CNC lathe works will enable you to fully exploit its potential. This article will give you some insights into how a CNC lathe operates.

CNC lathes possess the following components: bed, headstock, tailstock, and tooling station. The former is a static part that supports the workpiece. The latter supports one end while the former rotates it. Station for the cutting implements is meant for mounting those tools involved into machining processes.

Know your machine’s controls: Each button and knob on its control panel has specific purpose as well as an individual feature in it, also go through its menu structure to comprehend how it functions. In order to operate safely and efficiently, learn basic operations and selection plus adjustment of cutting tools should be considered.

Programming CNC lathes: Programming is about creating a path that directs the cutter along while it machines’ parts or surfaces of the workpiece; typically this is done using G-code that is usually generated by CAD/CAM software packages.

For safe running of CNC lathes, always adhere to their manufacturers safety instructions like putting on appropriate safety wears such as ear muffs, glasses among others such as goggles or hearing protection wear. By familiarizing yourself with these aspects such as components of your machine, programming styles

Precision is indispensable in contemporary manufacturing industries. The need for parts of high quality and precision continues to grow, thus making CNC lathe machining one of the leading technologies that can meet such demand. This paper discusses the role played by CNC lathe machining in industrial development.

CNC lathes are high precision machines which blend advanced technology with traditional lathes features and machine parts with accuracy as well as reproducibility using computerized axes. Reduced human errors and increased control make possible accurate and high-quality parts production.

The versatility of CNC lathes allows them to work on a wide range of materials, ranging from soft metals to hard composites. Because of this, manufacturers can now make intricate shaped components including those having narrow tolerances or unique material characteristics.

Put simply, CNC lathe machining changes what “precision” means in modern industry. It combines advanced technology and traditional lathe capability leading to production of highly precise components that have no rivals regarding their level of accuracy or repeatability.

Dongguan Xinteng Electronics Co., Ltd. was established in Chang'an Town, Dongguan, controlled by Xinteng Technology, focusing on R&D, production and sales: pogo pins, pogo pin connectors, magnetic connectors, magnetic charging cables, precision hardware accessories, etc.Since established, we has set up a professional, efficient and experienced project research and development team. Taking quality as the foundation, strictly control the market, research and development, manufacturing, testing, sales, after-sales service and other links, to provide customers with high-quality, competitive products and services.

We have rich experience in R&D team of 12 people, projectmanagement team of 10 people; Always serve attentively tosolve customers' worries.

We are a source factory, with ISO quality systemmanagement,quality assurance.

So far, we have successfully developed more than 100products for customers.

We implement process-specific solutions according tocustomer requirements.

CNC machine tools are capable of continuous operation, rapid tool changes and automated process control, ensuring high-precision part manufacturing, reducing human intervention, improving production efficiency and consistent product quality.

CNC lathe programming can optimize machining efficiency by implementing advanced strategies such as high-speed machining, optimizing tool paths to reduce unnecessary movements, and utilizing simulation software to detect and correct any potential issues before actual machining begins.

ool life in CNC lathe machining is managed through various techniques, such as monitoring tool wear, using cutting fluids or lubricants to reduce friction and heat, and implementing proper cutting parameters like cutting speed, feed rate, and depth of cut.

CNC lathe programming involves creating a sequence of instructions, typically using G-code, to guide the machine's movements. These instructions specify tool paths, cutting speeds, depths, and other parameters necessary for machining the desired part.

CNC lathes can machine a wide range of materials, including metals (such as steel, aluminum, and brass), plastics, and even certain types of wood. The specific capabilities depend on the machine's design, cutting tools, and cutting parameters.