Note: Our email addresses are only '[email protected]' '[email protected]' '[email protected]' Check the email addresses letter by letter to prevent scams

The reliable contact of the Pogo Pin connector ensures stable transmission of data and power, even in the presence of vibration or movement. By lowering impedance and maintaining a low-resistance connection, they help maintain signal quality and prevent distortion.

Today in this digital era of fast moving world, high-speed data transmission is essential for a good conversation and work. Reliable and fast data transfer is an important function that these spring pin connectors perform among electronic devices.

Spring Pin Connector Advantages

1. Maintain consistent contact force- This is crucial for high speed data transmission because it reduces signal loss and interference. They offer a reliable connection even in cases where the equipment may shake or move slightly due to their pins being spring-loaded.

2. Low resistance and low impedance-This type of connectors allows faster and more efficient data transfer through reduced resistance, which means that information will reach its destination in minimum delay time; besides they maintain signal integrity by having low impedance hence reducing chances of data corruption during transmission.

3. Excellent Signal Quality for High-Speed Data Transfer Protocols like USB, HDMI Or Ethernet: Whether it’s transferring big files, streaming HD videos or real-time data analysis- Pogo Pin Connectors offer enough bandwidth as well as performance to allow quality signals.

4. Used widely on several electronic devices such as smartphones, tablets, laptops and high-performance servers; they are truly ideal for space-constrained applications without sacrificing performance because of compact shape And compatibility with various form factors.

Pogo pin connectors play a major role in the quick delivery of information from one device to another by maintaining constant contact forces along with lower resistances and impedances so as to ensure smooth communication between electronic devices through faster data transmission rate. Be it consumer electronics, industrial equipment or automotive systems – pogo pin connectors bridge the connection gap required in this digital age.

The automobile manufacturing sector is always evolving as cars are becoming more and more connected and complex. Boosting connectivity and improving reliability, for instance, Pogo pin connectors now play a key role in automotive electronics.

Pogo pin connectors comprise spring-loaded pins that ensure consistent contact force to the electrical connection even when experiencing vibrations, shocks or temperature fluctuations.

These pogo pin connectors also show high speed data transfer rates necessary for modern automotive systems. High-bandwidth signals such as video streams, sensor data, and diagnostic information can be transmitted effectively through these connectors because they cater for the emerging requirements of real-time data processing and communication.

Further still, these pogo pin connectors can enhance reliability in automotive applications. These work well in regards to harsh operating conditions including high temperatures, humidity levels and contamination. The use of building materials like corrosion-resistant metals as well as rugged components ensures long life thereby reducing possibilities of failure of connections or intermittent signal loss.

Traditional connectors have many disadvantages which makes Pogo Pin connectors popular in the electronics industry. These are exceptional connectors with one of a kind features and capabilities that make them work best for different applications. Let us look at this further by exploring the benefits of Pogo Pin connectors.

Pogo Pin connectors have their own stand out operational efficiency, spring-loaded pin insertion and removal can be done quickly making it easy and fast to assemble or disassemble. This is more important when you are engaged in production environment or if devices need to connect and disconnect frequently.

Moreover, Pogo Pin connector supports high current as well as high-speed data transmission. Designed to meet tough electrical criteria, these offer efficient power delivery and rapid data transfer levels. Whether you need to charge your device, send huge files or stream HD content, Pogo Pin connectors are built with necessary performance.

Pogo Pin connectors are often preferred over other types due to their reliable connections, quick operation, long life span, capacity for handling heavy current flow and super-fast signal speed. No matter whether it is consumer electronics or medical instruments or auto mobile systems or industrial appliances; then the use of pogo pin connectors ensures better performance along with increased dependability.

To ensure a smooth communication and optimum performance in the field of electronic devices, data transfer speed needs to be fast and efficient. Next, read about how unique design and features make pogo pin connector affect data transfer speed.

Pogo pin connectors reduce resistance so that data can move easily between connected devices; this prevents latency and ensures real-time data transfer. In addition the pogo pin connectors are very suitable for high-frequency applications, such as those requiring high-speed data transmission.

This is because they have better mechanical and electrical durability compared to other types of connectors. For instance, these connectors can endure thousands of plug-unplug cycles with minimal signal disruption which makes them perfect for applications demanding frequent connection and disconnection of devices.

Furthermore, one needs to know that pogo pin connector’s impact on data transfer speeds cannot be limited to its technical characteristics only. These types of connectors conform to industrial standards and requirements set by the manufacturers hence making them compatible with several types of electric gadgets.

Dongguan Xinteng Electronics Co., Ltd. was established in Chang'an Town, Dongguan, controlled by Xinteng Technology, focusing on R&D, production and sales: pogo pins, pogo pin connectors, magnetic connectors, magnetic charging cables, precision hardware accessories, etc.Since established, we has set up a professional, efficient and experienced project research and development team. Taking quality as the foundation, strictly control the market, research and development, manufacturing, testing, sales, after-sales service and other links, to provide customers with high-quality, competitive products and services.

We have rich experience in R&D team of 12 people, projectmanagement team of 10 people; Always serve attentively tosolve customers' worries.

We are a source factory, with ISO quality systemmanagement,quality assurance.

So far, we have successfully developed more than 100products for customers.

We implement process-specific solutions according tocustomer requirements.

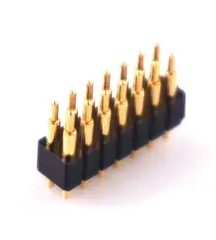

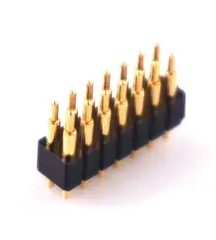

Traditional connectors often use a mating system with pins and sockets, where physical contact is made through the insertion of pins into the corresponding sockets. pogo pin connectors, on the other hand, utilize spring-loaded contacts. These contacts, also known as pogo pins, consist of a plunger and a spring mechanism that provides a reliable electrical connection when compressed against a contact pad or surface.

Pogo pin connectors offer several advantages over traditional connectors. They provide a reliable and repeatable electrical connection without the need for soldering. They have a low insertion force, making them easy to use and reducing the risk of damage to sensitive components. Pogo pin connectors also have a compact design, making them suitable for applications with space constraints.

When selecting a spring pin connector, you should consider the current carrying capacity, stroke distance, spring force, plunger diameter and overall durability. The specific choice is based on your needs and is provided for reference only.

Pogo pin connectors can handle high-speed data transfer, and their design and construction allow for reliable and low-resistance connections, making them suitable for applications that require fast, accurate data transfer.

It is important to consider factors such as pin alignment, pin spacing, and contact force requirements. Proper alignment and matching pin configuration ensure a safe and reliable connection between the pogo pin connector and the target device.