What are the common internal structures of pogo pins?

Pogo pins are connectors’ accessories that come in handy in electronic connections. These are used in several fields such as diagnostic instruments, cell phones, and mobile circuit boards. It is important to comprehend the internal structures of pogo pins to aid selection of suitable analyses. XINTENG is a prominent provider of pogo pins high-quality solutions for various forms of applications.

Key Internal Structures of Pogo Pins

Pin Body:

The pin body is the major portion of the pogo pin. It is mostly composed of hard materials or hard alloys such as brass and stainless steel for protection and durability against deterioration. the pin body is an essential part of a pogo pin since any design that affects the pin’s structure affects its performance and electrical conductivity.

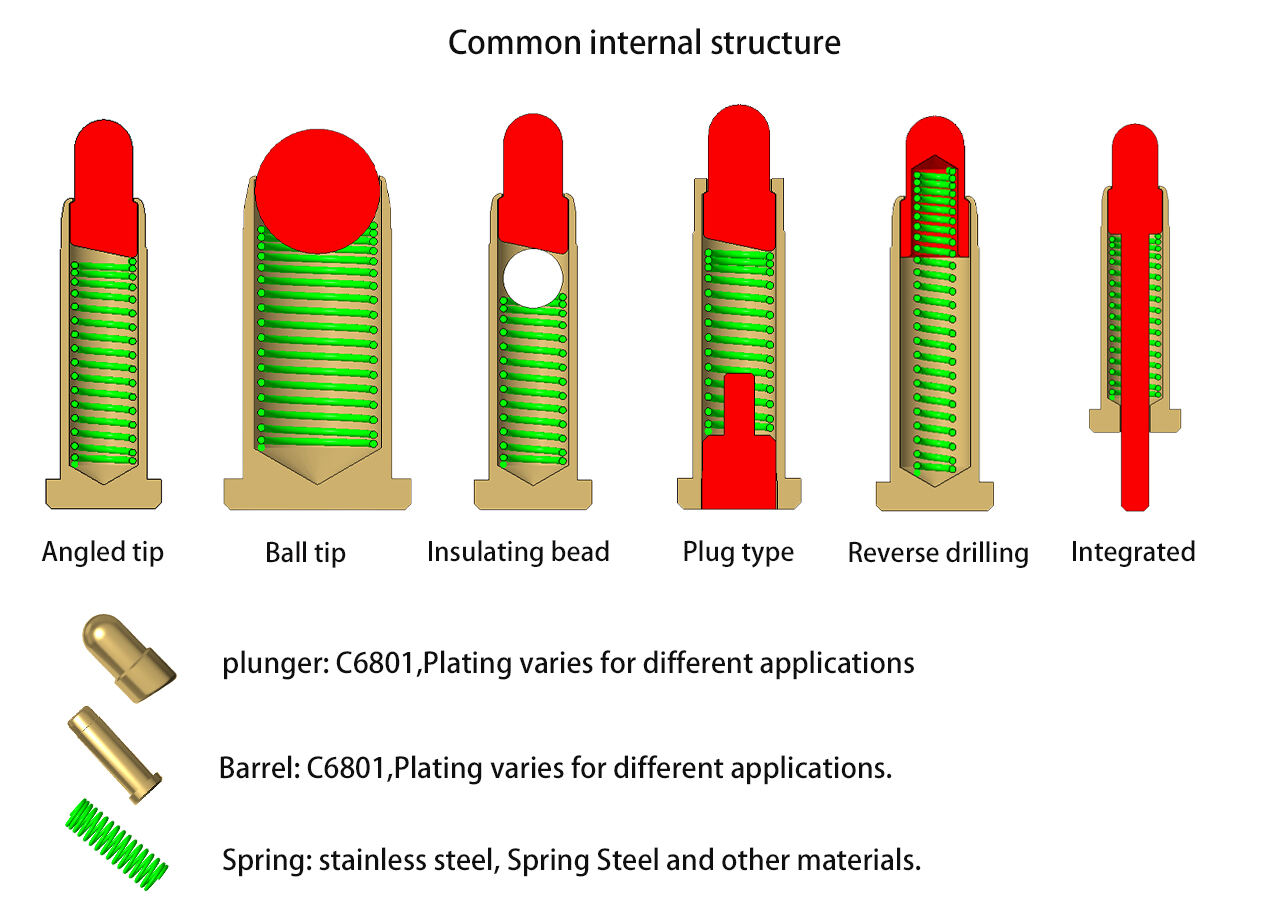

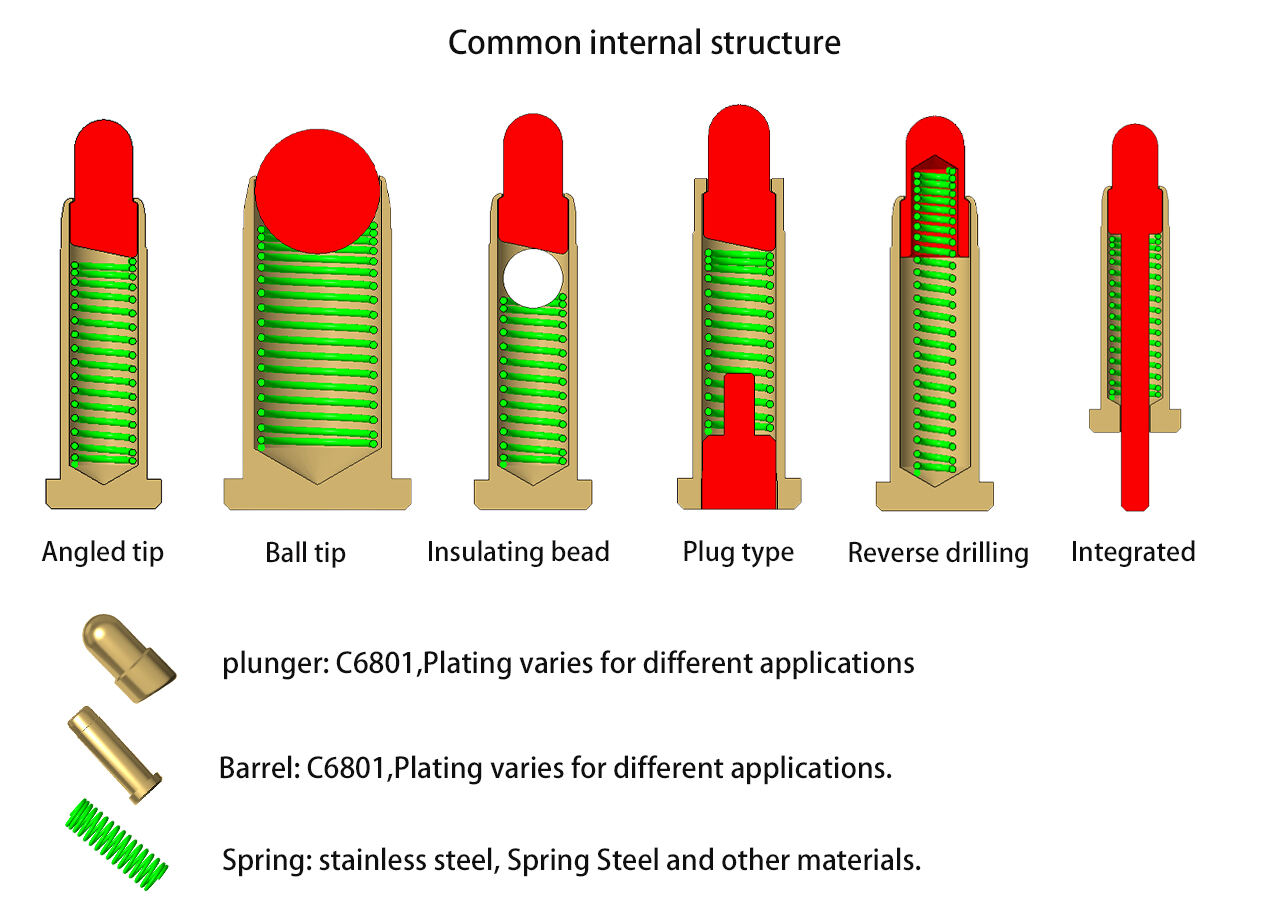

Spring Mechanism:

The pogo pin has a spring as one of its vital structures to extend and retract the service pin due to the elastic energy stored in the spring after compress. The spring is made using very strong steel and designed not to fail with repeats application. This spring also plays the role of ensuring that there is contact with the surfaces to be mated.

Tip:

The shape of the pogo pin tip is very different and may be round, flat faceted or any other shape as may the application require. The physical design of the tip influences on how much contact is made and how well electricity is conducted through the pogo pin. XINTENG provides a set of tip designs with different electrical and mechanical parameters.

Housing:

The housing surrounds and protects all internal parts of the pogo pin, which adds sturdiness to the structure. It is constructed so that the pin and the spring can be fast locked and compressed with ease into multiple gadgets. The component used for making the housing should be strong enough for it to survive climatic conditions.

Contact Plating:

Contact plating is an additional layer provided to pogo pins for improving conduction and reducing the risks of corrosion. Gold, Nickel and Tin are the most common plating materials used and need to be mentioned. The type of plating used will affect how well a pogo pin functions and how long it will last in that specific application.

Conclusion

Recognizing the fundamental internal features of pogo pins will aid in the proper selection of components for your electronic needs. Many shapes and specifications of pogo pins will be offered by XINTENG, thus guaranteeing their proper functioning for different purposes. Understanding the pin body, spring mechanism, tip, housing, and contact plating will help you do effective decision making about your projects, thereby increasing their efficiency and dependability.

Hot News

-

Challenges for Pogo pin manufacturers in the AI era

2023-12-14

-

Teach you how to understand Pogo pin spline structure

2023-12-14

-

What products can Pogo pin be used in?

2023-12-14

-

How to choose Pogo pin connector

2023-12-14

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

SR

SR

UK

UK

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

SW

SW

GA

GA

CY

CY

IS

IS

BN

BN

BS

BS

NE

NE