Precision Machining Innovations: CNC Lathes Lead the Way in Advanced Manufacturing Technologies

CNC Lathes are indispensable and undoubtedly be the most important as far as the advanced manufacturing technology is concerned. These machines allow us to manufacture complex parts accurately and reliably with the help of computer automation machines. At XINTENG, quality ensures high standards and this is why we employ CNC Lathes for our production work to meet client expectations.

Trends already established in CNC Lathe technological development

It is pertinent to note that significant progress was made over the past few decades which enabled the development of CNC lathes that feature advanced software, advanced hardware and enhanced materials to manufacture bushing parts. Improvements such as increasing efficiency, reducing downtimes and enhancing capabilities have been witnessed. Our zeal in being leaders in these trends enables us to always be enables our production processes to be up to date.

Short Lead Times for Production Runs

There is greater customization processes that are fully automated. CNC lathes are perhaps the most popular machines for small, medium, and large scale production. These machines allow us to rest and implement new settings when need be and cover many orders be it a prototype or mass production.

CNC Lathes and their role in the optimal level of quality control

On a rotary, cnc Lathe has very little slack, Close tolerances combined with the power to do multi operations on a single machine makes it perfect making sure each piece is crafted perfectly.

Upcoming Developments in the Operation of CNC Lathes The technological advancements in the CNC industry has encouraged the incorporation of the CNC Lathes. Other emerging technologies, like AI and the IoT also enables further implementation of CNC Lathes in the previously unexploited fields. Finally, with the continual growth of the manufacturing sector, CNC Turning can be projected to have further engagement in the future. Future developments will witness the deployment of computers to optimize almost every aspect of lathes, further increasing their applicability across the manufacturing sector. As mentioned previously, the large scale integration of lathes with other emerging technologies, will widen trusted and educational practices among CNC lathes operators. For instance, the integration of CNC lathe training and AR or VR technologies allows users to grasp more strategies at an accelerated pace. It is true that CNC lathes were, are and will remain one of the most important components in terms of precision engineering. Conclusion We are continuously utilizing the most advanced CNC Lathes equipment in the XINTENG community because we believe that it is essential in order to meet precision machining needs. To add onto that, we believe in utilizing these complex pieces of machinery, to always provide value to our customers.

Hot News

-

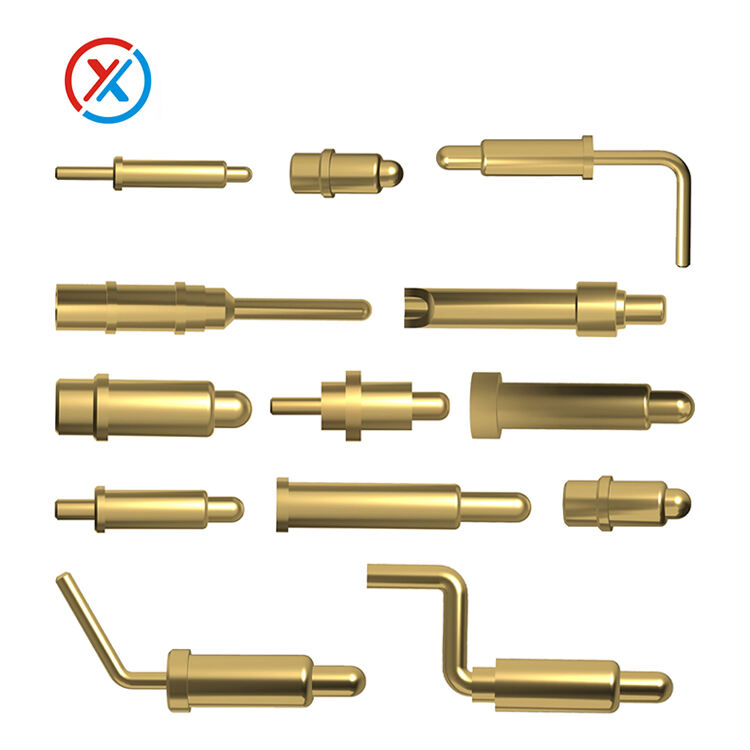

Challenges for Pogo pin manufacturers in the AI era

2023-12-14

-

Teach you how to understand Pogo pin spline structure

2023-12-14

-

What products can Pogo pin be used in?

2023-12-14

-

How to choose Pogo pin connector

2023-12-14

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

SR

SR

UK

UK

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

SW

SW

GA

GA

CY

CY

IS

IS

BN

BN

BS

BS

NE

NE