- Overview

- Inquiry

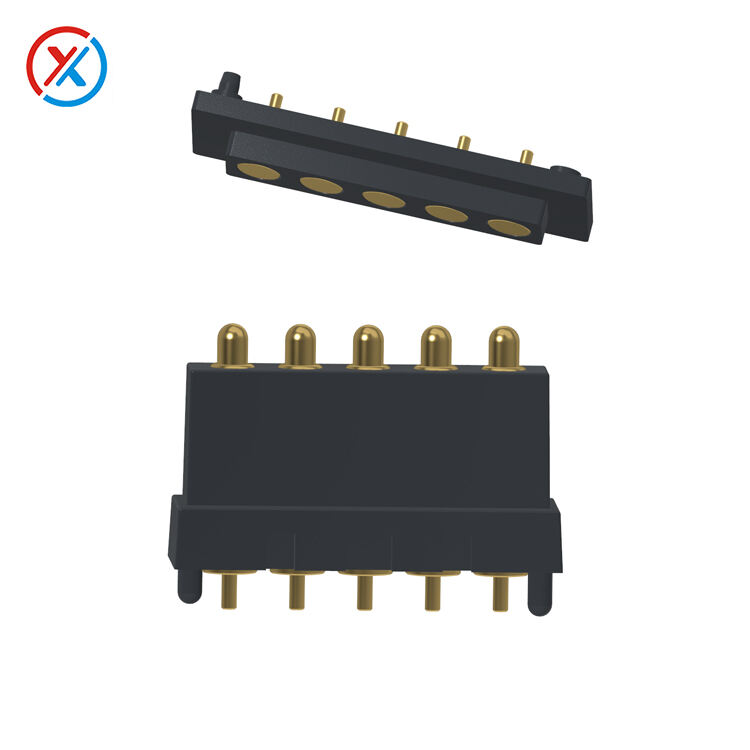

- Related Products

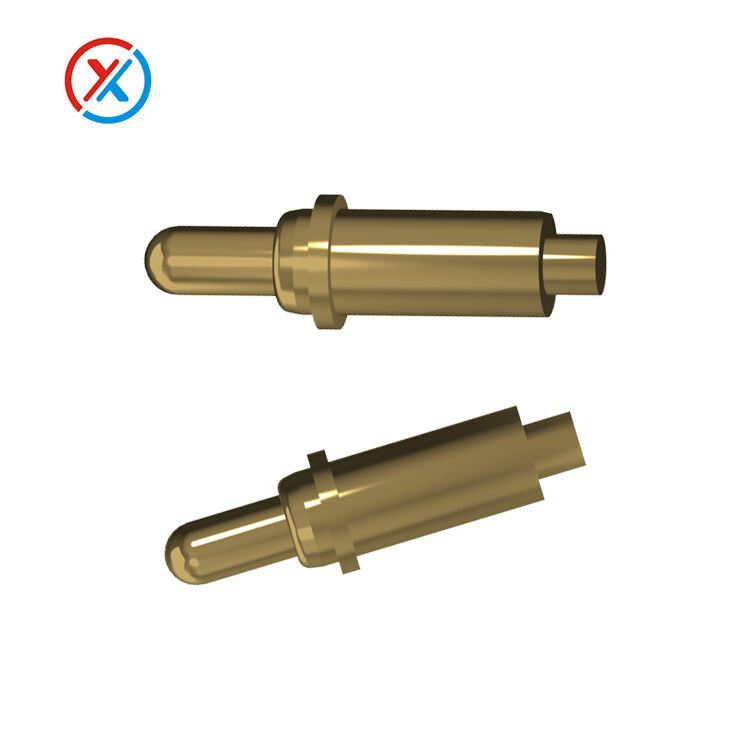

1、Product features:

1)100% environmentally friendly materials that meet RoHs and REACH requirements.

2)Automatic riveting press assembly, automatic inspection and shipment.

3)Tolerances can be controlled to ±0.01mm.

4)Contact impedance ≤ 15m Ω.

5)The life span can reach more than 1000000 times.

6)No mold opening, convenient customization, cost saving.

7)The elasticity can be adjusted according to the requirements.

8)Small spacing and space saving

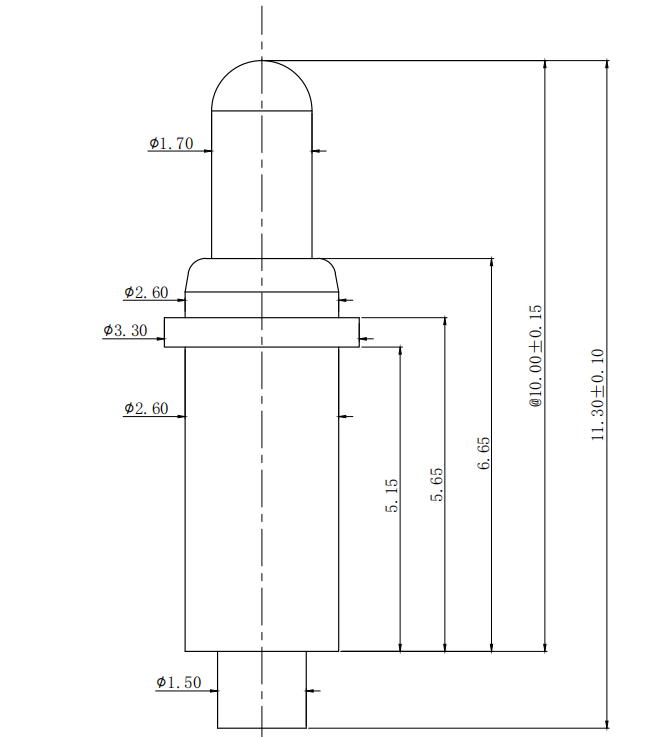

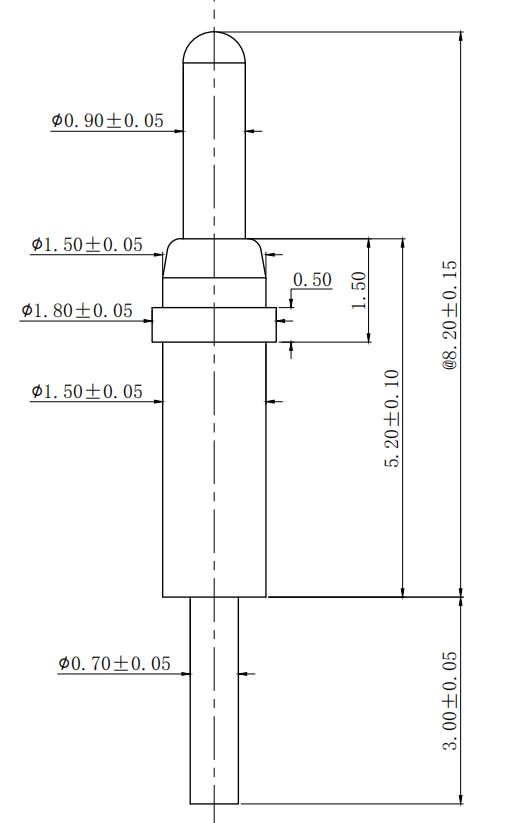

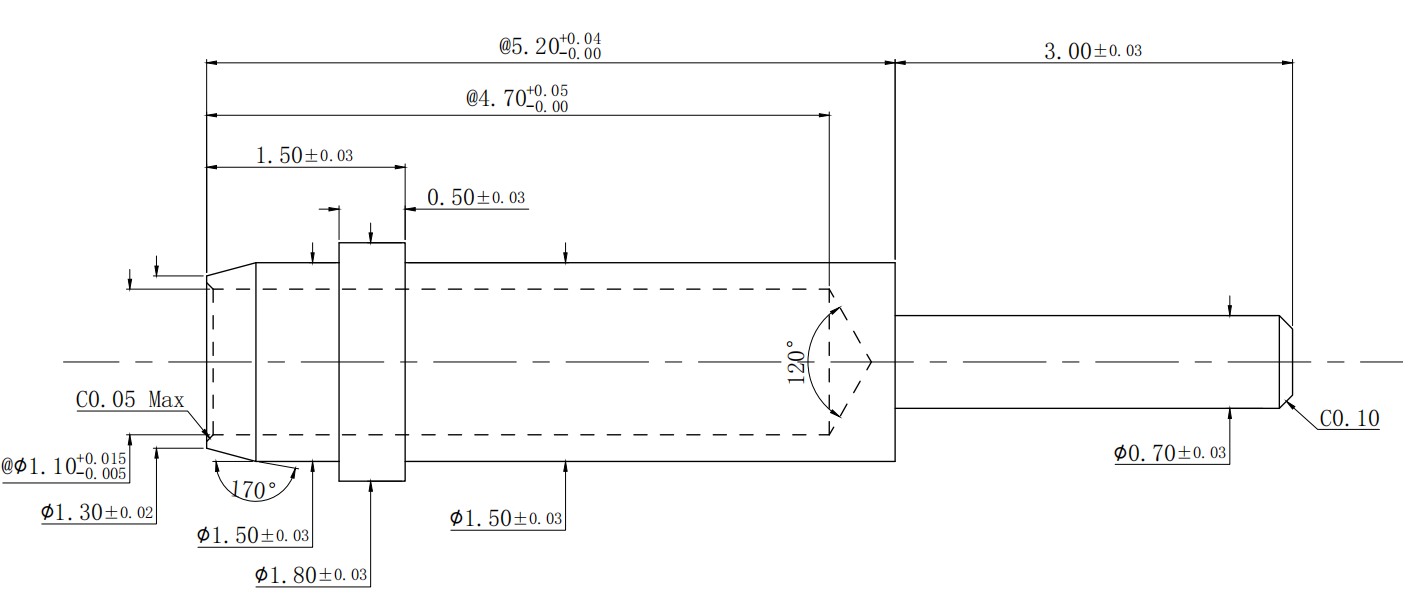

2、Product parameters:

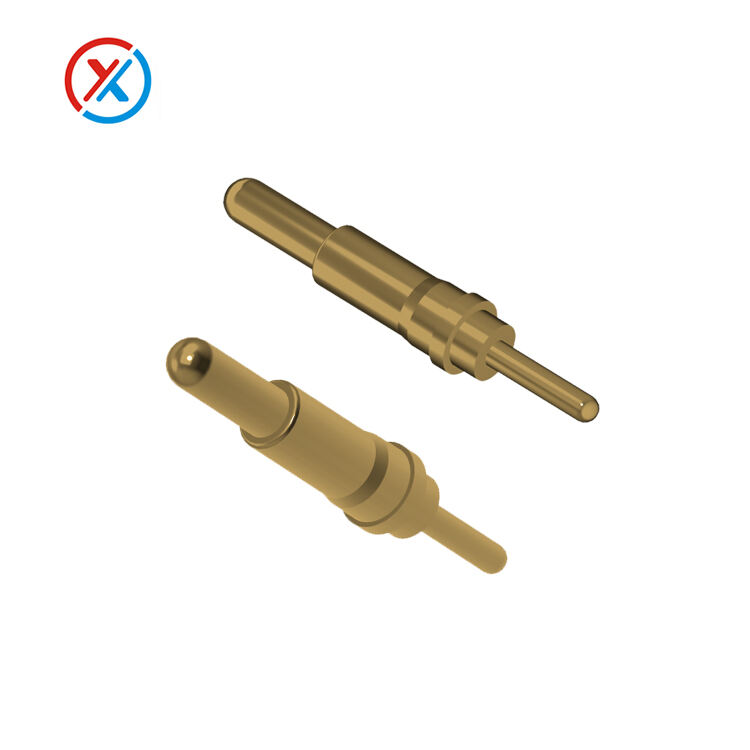

pogo pin male and female,Used in consumer electronics, smart home, industrial electronics,

automotive electronics, medical equipment, aerospace, communication equipment

| ITEM | DATA #1 |

| Model | pogo pin-1385 |

| Metallic materials | Brass C6801 |

| PIN electroplating | Plating 5u"Au over 60~100u" Ni. |

| Work schedule | 1.0mm |

| Elastic force | 80g±20g |

| Contact resistance of spring pin | 50mOhm Max. |

| Rated voltage | 12V |

| Rated current | 1.0A 2.0A 3.0A |

| Mechanical life | 1000,000 cycle Min |

| Salt spray test | 48H-96H |

| Packing | PE bag / reel packing |

| Material and coating conform to ROHS and REACH standards | |

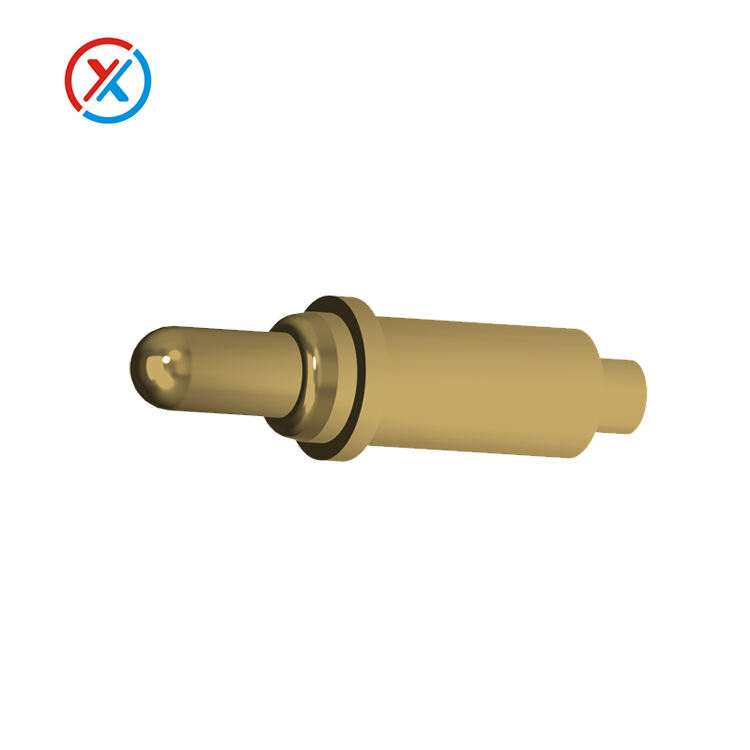

3、Pogo pin scheme can be customized according to your requirements.

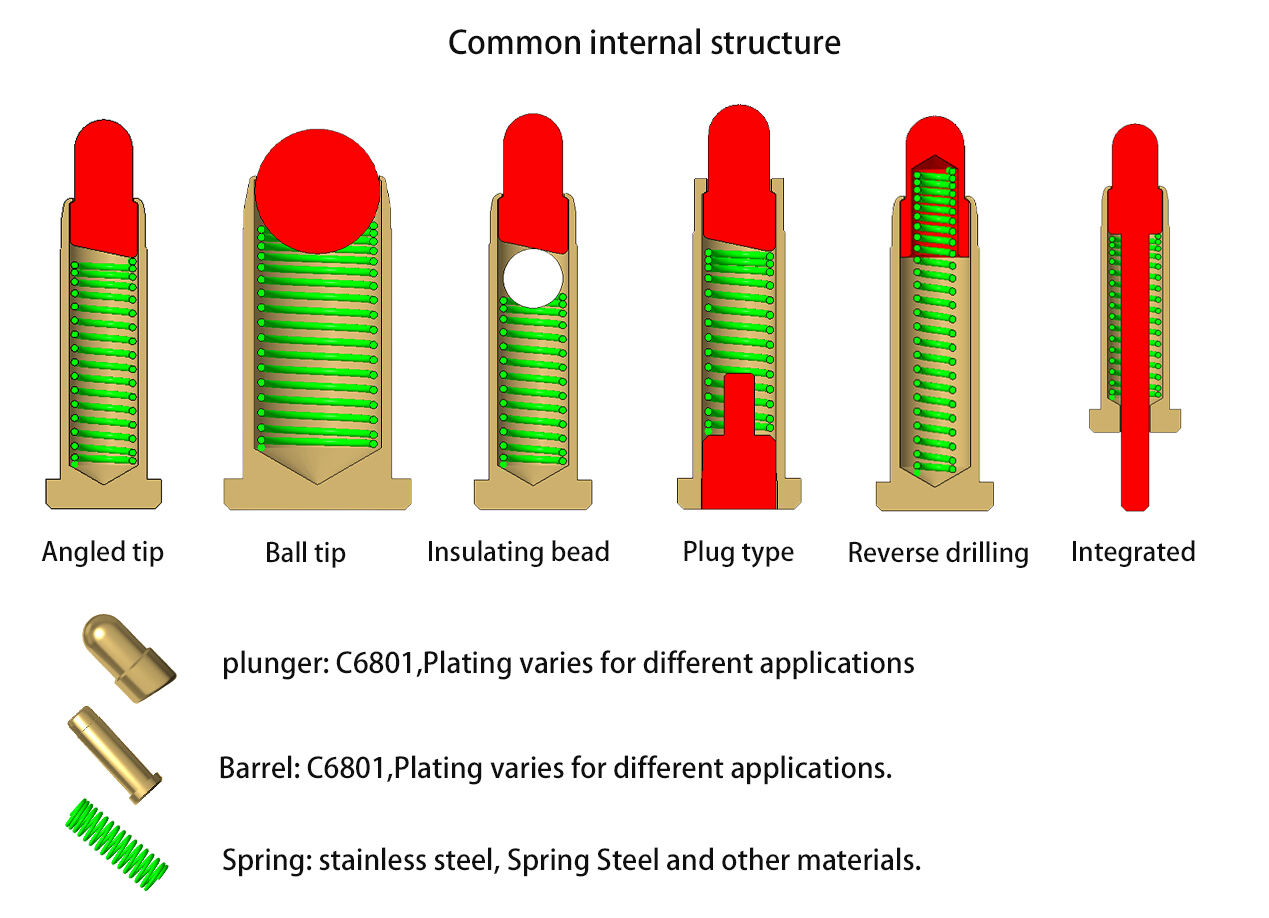

1. Shape structure: SMT,DIP, bend, double pin, welding wire structure, integrated type.

2. Material: C3604 C6801.

3. Elasticity: ≤ 15g.

4. Rated voltage / current: ≤ 120V, ≤ 40A.

5. Connection method: 90 °, 180 °or other angle.

6. Mother end assembly style; DIP, 90 °bending, welding wire, glue wrap molding, etc.

7. Mother end positioning mode: concave and convex groove, sealing ring, clamping lock, positioning ear, positioning column, in-mold injection molding.

Let us be your most reliable supplier!

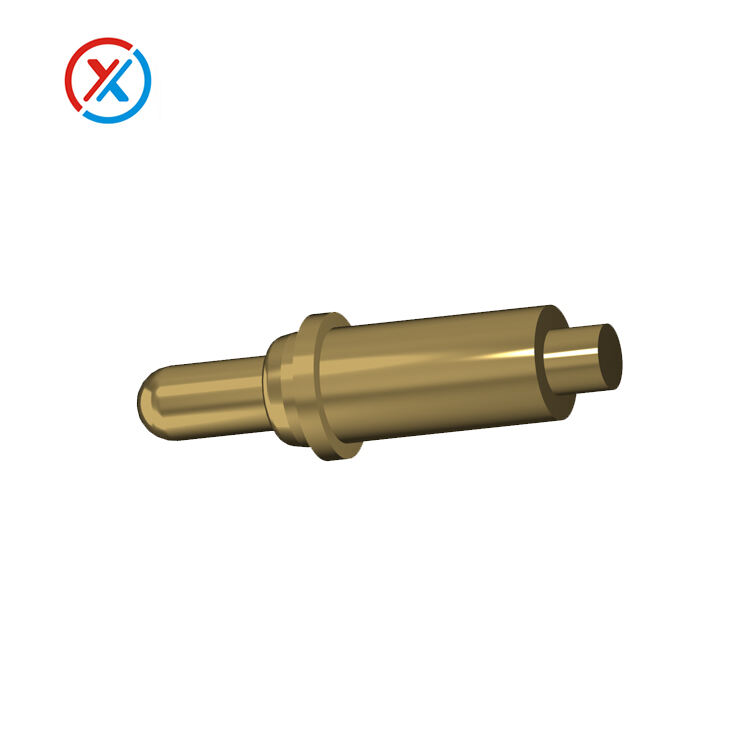

4、 Advantages of pogo pin

Reliability: Pogo pins provide a stable electrical connection and maintain good contact performance even after multiple insert/pull out operations.

Durability: Due to their internal spring structure, pogo pins can withstand a large number of uses without affecting performance and have a long service life.

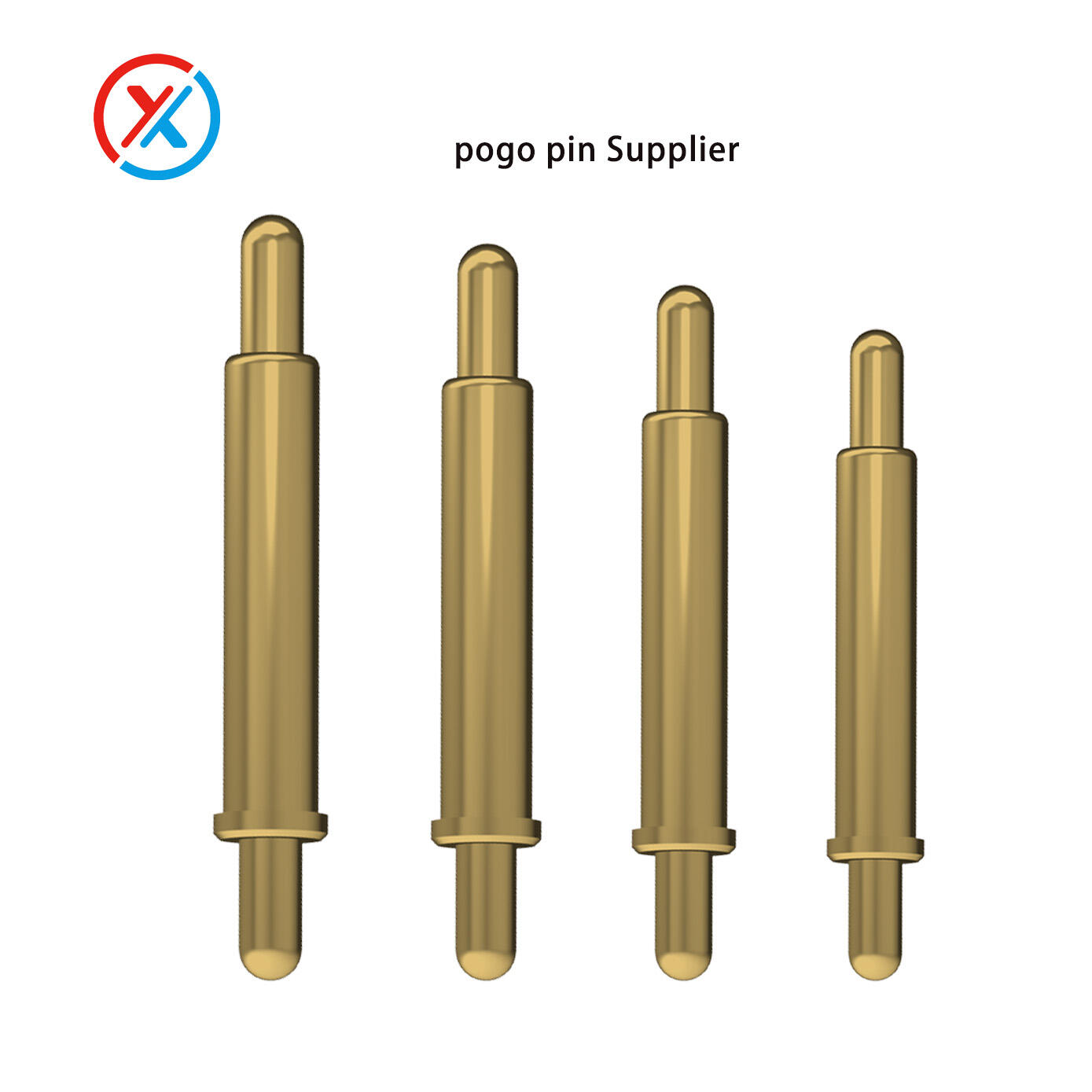

Flexibility: The design of Pogo pins is flexible and can be tailored to the length, diameter and contact type of different applications.

Accuracy: High precision can be achieved in the manufacturing process, ensuring that each pin can accurately touch the corresponding pin.

Reduce wear: In some application scenarios, pogo pins can reduce wear on the butt equipment because they are able to absorb a certain amount of mechanical stress without transferring it directly to the connector.

Easy and fast: No welding or other permanent fixing method is required when connecting or testing with pogo pins, making replacement or maintenance easier.

Strong adaptability: can work in a variety of environments, including high temperature, low temperature, high humidity and other harsh conditions.

Space saving: For designs that need to save space, pogo pins can achieve efficient connections in limited Spaces due to their small size.

5、pogo pin application

Circuit board testing, battery connectors, aerospace, consumer electronics, industrial automation, laboratory equipment, automotive electronics, etc

6、Company introduction

Xinteng Electronics belongs to a pogopin magnetic connector solution source factory, from design-R & D-production, one-stop service; mainly produces pogopin, spring pin connectors, magnetic connectors, magnetic charging lines and other precision hardware; factory area of 2700 square meters, R & D staff of 12 people, customized development products have 600 + items, obtained national patent certificate 80 +. At present, there are a variety of magnetic products to choose from, and it can also provide technical services for your product design and development to relieve your worries.

7、Product category

Xinteng company produces pogo pins, pogo pin connectors, magnetic connectors, magnetic data lines and other products. It is used for charging, data transmission or connection between internal components in consumer electronics industry, smart wearable, smart home appliances, medical beauty, Internet of Things equipment, drone equipment and other industries

Spring pin connector is a small precision electronic component, widely used in various electronic products, such as mobile phones, tablets, medical equipment, automotive electronic systems and so on. These connectors feature an elastic metal needle that deforms when subjected to pressure, allowing for a reliable connection to another port.

As a professional spring needle manufacturer, Xinteng provides a variety of models and specifications of spring needle products to meet the different needs of customers.

Hope to further communicate the details, to facilitate the rapid provision of products, thank you!

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

SR

SR

UK

UK

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

SW

SW

GA

GA

CY

CY

IS

IS

BN

BN

BS

BS

NE

NE