- Overview

- Parameter

- Inquiry

- Related Products

1、Product features:

1)100% environmentally friendly materials that meet RoHs and REACH requirements.

2)Automatic riveting press assembly, automatic inspection and shipment.

3)Tolerances can be controlled to ±0.01mm.

4)Contact impedance ≤ 15m Ω.

5)The life span can reach more than 1000000 times.

6)No mold opening, convenient customization, cost saving.

7)The elasticity can be adjusted according to the requirements.

8)Small spacing and space saving

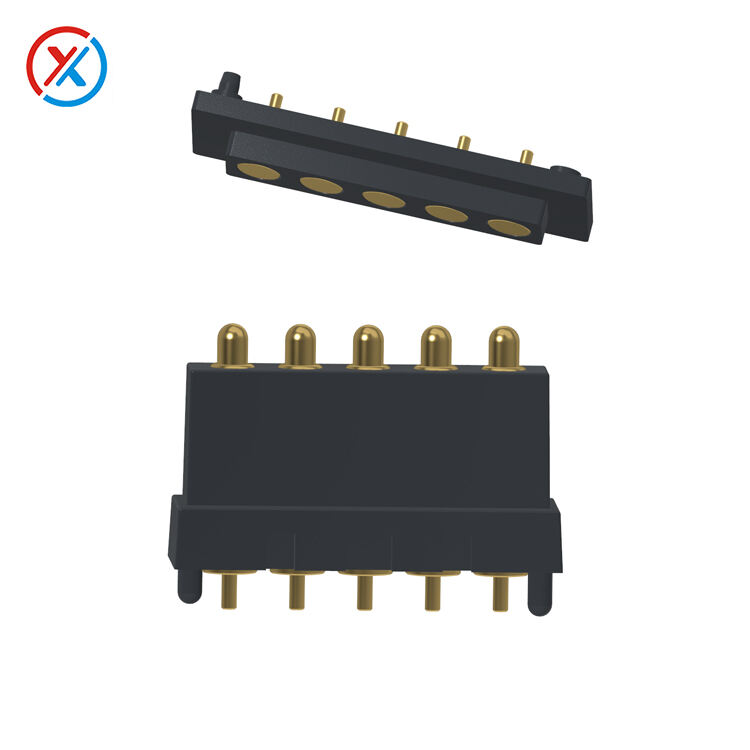

2、Product parameters:

| Applied to mobile device charging, beauty instruments, electronic cigarette equipment, consumer electronics, wearable technology and so on | |

| ITEM | DATA #1 |

| Model | SMT -1425 |

| Metallic materials | Brass C6801 |

| PIN electroplating | Plating 5u"Au over 60~100u" Ni. |

| Work schedule | 1.0mm |

| Elastic force | 80g±20g |

| Contact resistance of spring pin | 50mOhm Max. |

| Rated voltage | 12V |

| Rated current | 5.0A |

| Mechanical life | 1000,000 cycle Min |

| Salt spray test | 48H-96H |

| Packing | PE bag / reel packing |

| Material and coating conform to ROHS and REACH standards | |

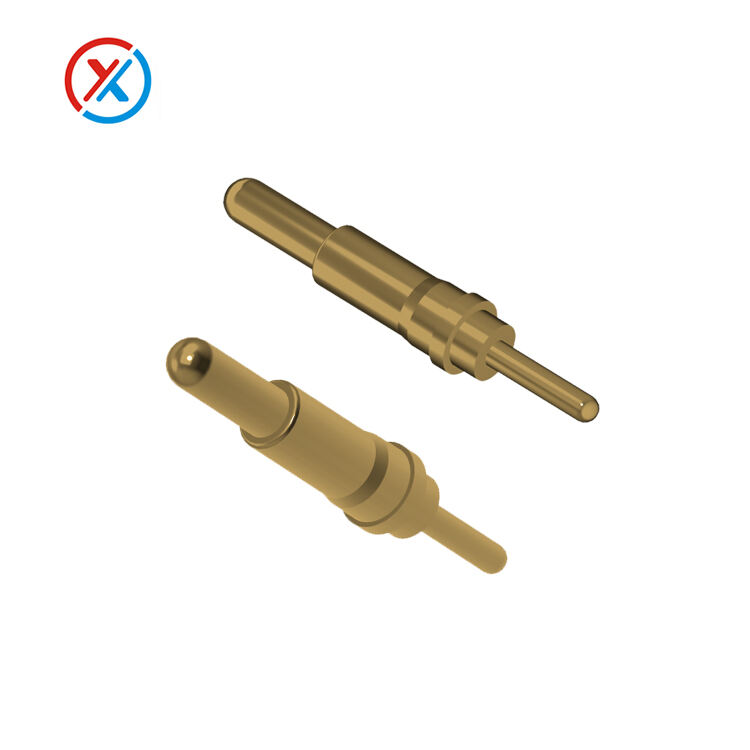

3、Pogo pin scheme can be customized according to your requirements.

1. Shape structure: SMT,DIP, bend, double pin, welding wire structure, integrated type.

2. Material: C3604 C6801.

3. Elasticity: ≤ 15g.

4. Rated voltage / current: ≤ 120V, ≤ 40A.

5. Connection method: 90 °, 180 °or other angle.

6. Mother end assembly style; DIP, 90 °bending, welding wire, glue wrap molding, etc.

7. Mother end positioning mode: concave and convex groove, sealing ring, clamping lock, positioning ear, positioning column, in-mold injection molding.

Let us be your most reliable supplier!

4、High-current pogo pin product advantage

The high-current pogo pin is a connector used in electronic devices, which is widely used because it can withstand large currents and has good elastic contact capacity. Here are some of the main advantages of high-current spring pins:

High reliability:

In the case of frequent insertion and removal, the spring needle can provide a stable electrical connection without damage.

The spring structure ensures good contact even in the case of slight position deviation.

Durability:

It is usually made of wear-resistant materials, such as stainless steel or gold-plated copper alloys, to ensure stable performance under long-term use.

It can withstand more than tens of thousands of insertion and removal operations.

Strong adaptability:

It can be applied to different environmental conditions, such as high temperature, humidity and other harsh environments.

Depending on the application scenario, different materials and designs can be selected to meet special requirements.

Save space:

Compact design, can achieve efficient connection in a limited space, suitable for the internal connection of miniaturized electronic products.

Easy to maintain:

When a spring pin is damaged, it can be replaced separately rather than replacing the entire component, reducing maintenance costs.

Low contact resistance:

The optimized design reduces the resistance of the contact surface, ensuring high current transmission efficiency and low heat generation.

Flexibility:

The elasticity of the spring and the length of the needle can be adjusted according to the actual needs to adapt to different application requirements.

These characteristics make high-current spring pins an indispensable part of many electronic devices, especially in applications where reliable, durable connections are required.

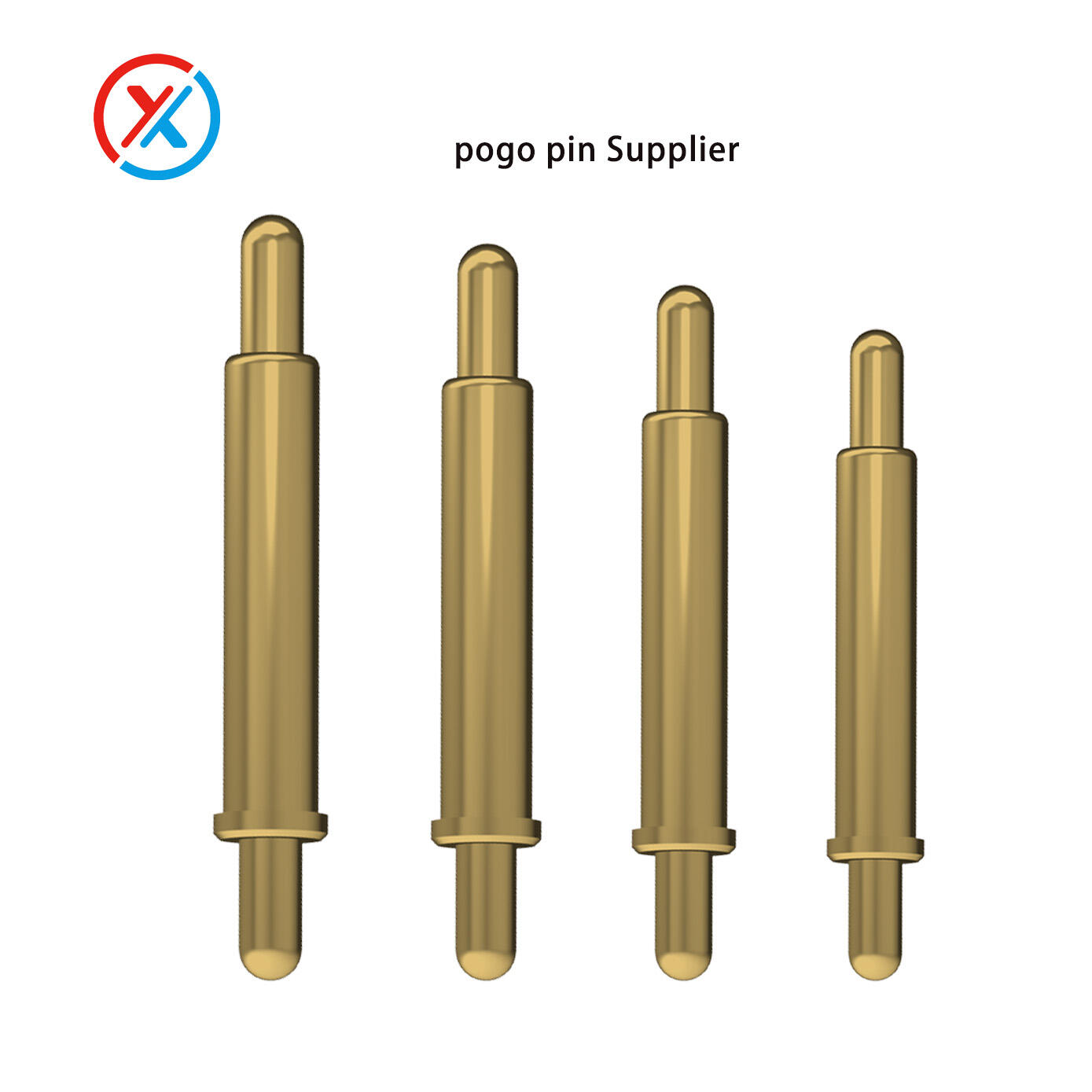

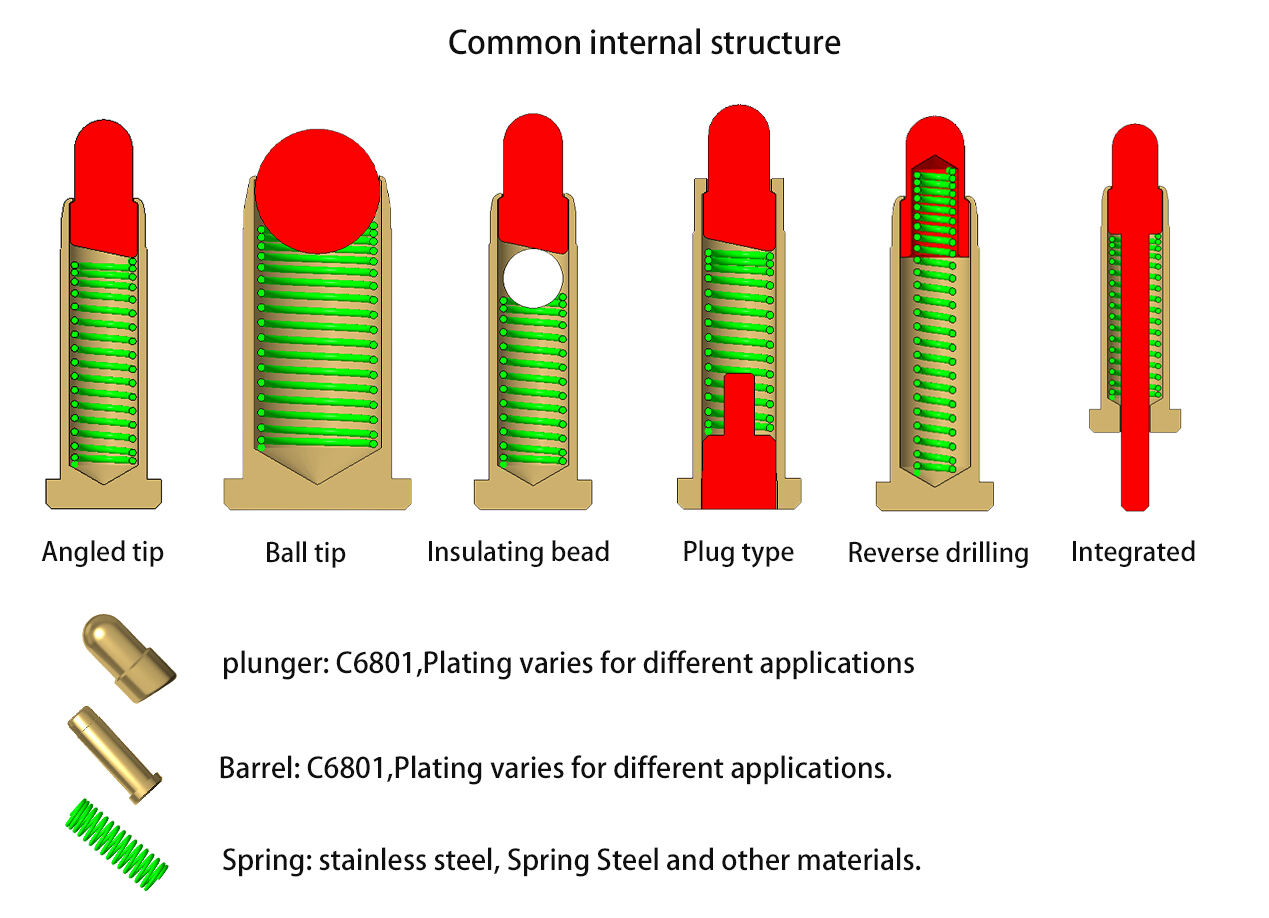

5、Internal structure of a pogo pin

Contact End:It is usually gold-plated or silver-plated with metal tips to improve electrical conductivity and prevent corrosion.

Insulator :Located on the outside or inside of the needle body to isolate the electrically charged part and prevent short circuit.

Needle Body:It is usually made of metal, such as stainless steel or copper alloy, and is coated to improve durability and electrical conductivity.

Spring material:Commonly used materials include stainless steel, phosphor bronze, beryllium copper, etc., and sometimes special alloy materials are used.

Coating:In order to improve electrical conductivity and prevent oxidative corrosion, the contact surface of the spring needle is often plated with gold, silver, rhodium and other metals.

6、Company introduction

Xinteng Electronics belongs to a pogopin magnetic connector solution source factory, from design-R & D-production, one-stop service; mainly produces pogopin, spring pin connectors, magnetic connectors, magnetic charging lines and other precision hardware; factory area of 2700 square meters, R & D staff of 12 people, customized development products have 600 + items, obtained national patent certificate 80 +. At present, there are a variety of magnetic products to choose from, and it can also provide technical services for your product design and development to relieve your worries.

7、Product category

Xinteng company produces pogo pins, pogo pin connectors, magnetic connectors, magnetic data lines and other products. It is used for charging, data transmission or connection between internal components in consumer electronics industry, smart wearable, smart home appliances, medical beauty, Internet of Things equipment, drone equipment and other industries

Spring pin connector is a small precision electronic component, widely used in various electronic products, such as mobile phones, tablets, medical equipment, automotive electronic systems and so on. These connectors feature an elastic metal needle that deforms when subjected to pressure, allowing for a reliable connection to another port.

As a professional spring needle manufacturer, Xinteng provides a variety of models and specifications of spring needle products to meet the different needs of customers.

Hope to further communicate the details, to facilitate the rapid provision of products, thank you!

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

SR

SR

UK

UK

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

SW

SW

GA

GA

CY

CY

IS

IS

BN

BN

BS

BS

NE

NE