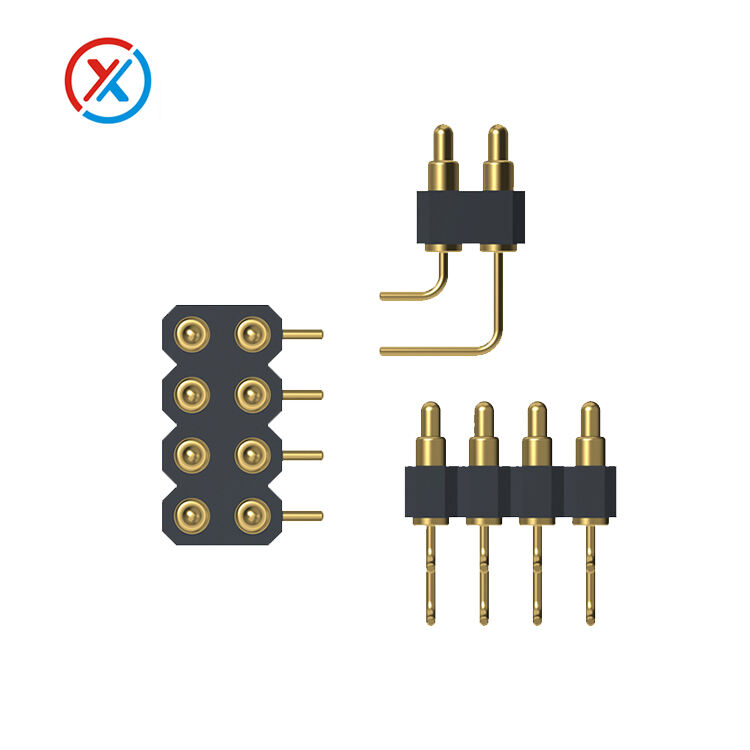

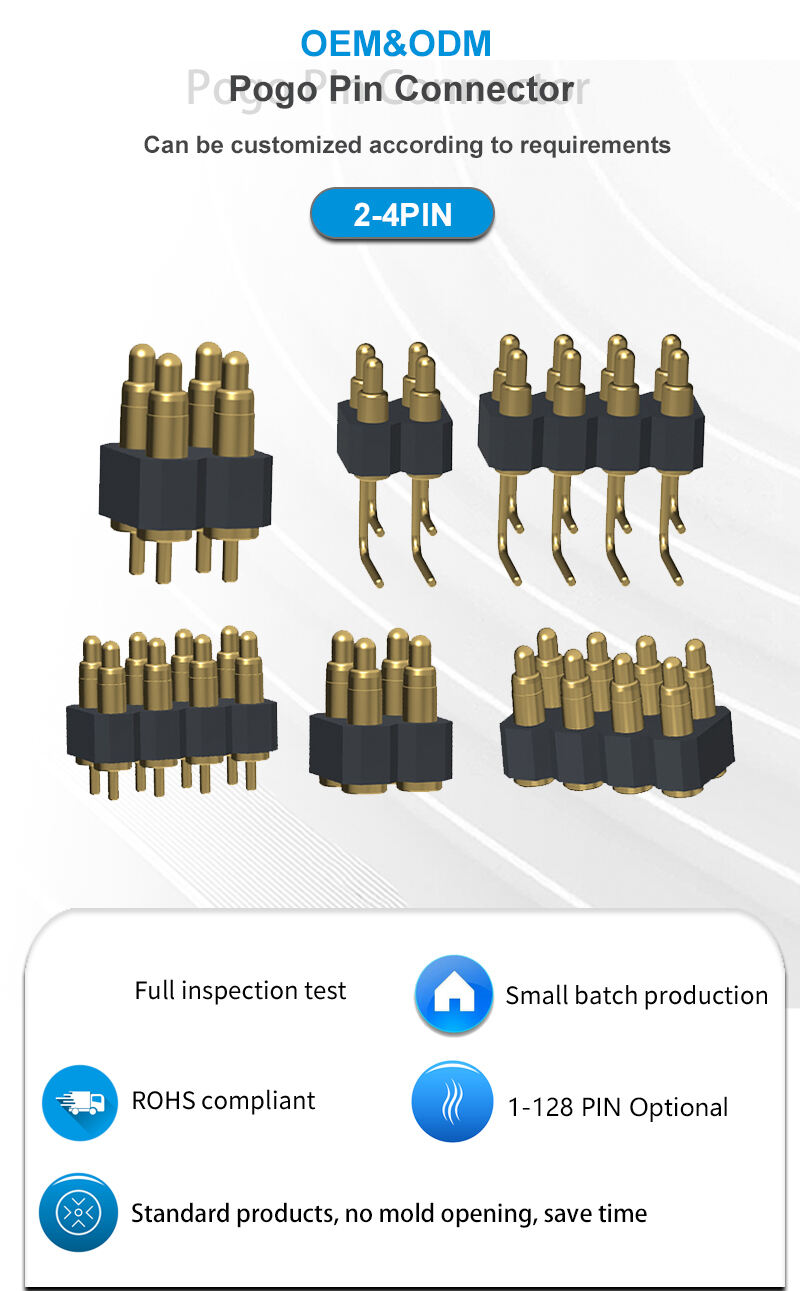

high current pogo pin connectors bend spring pin connector father and mother-4pin 2pin pogo connector pins

Product Name:4Pin Pogo pin connectors

Product model:Double row 4Pin Pogo pin connectors

Delivery time: 15-20 days

Type: non-standard

- Overview

- Parameter

- Inquiry

- Related Products

1、Product features:

1)100% environmentally friendly materials that meet RoHs and REACH requirements.

2)Automatic riveting press assembly, automatic inspection and shipment.

3)Tolerances can be controlled to ±0.01mm.

4)Contact impedance ≤ 15m Ω.

5)The life span can reach more than 1000000 times.

6)No mold opening, convenient customization, cost saving.

7)The elasticity can be adjusted according to the requirements.

8)Small spacing and space saving.

2、Product parameters:

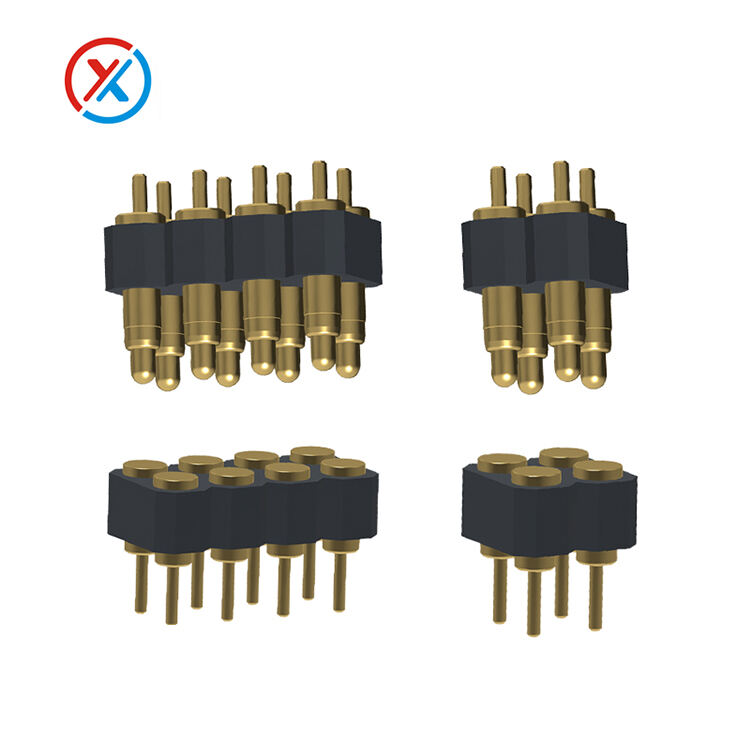

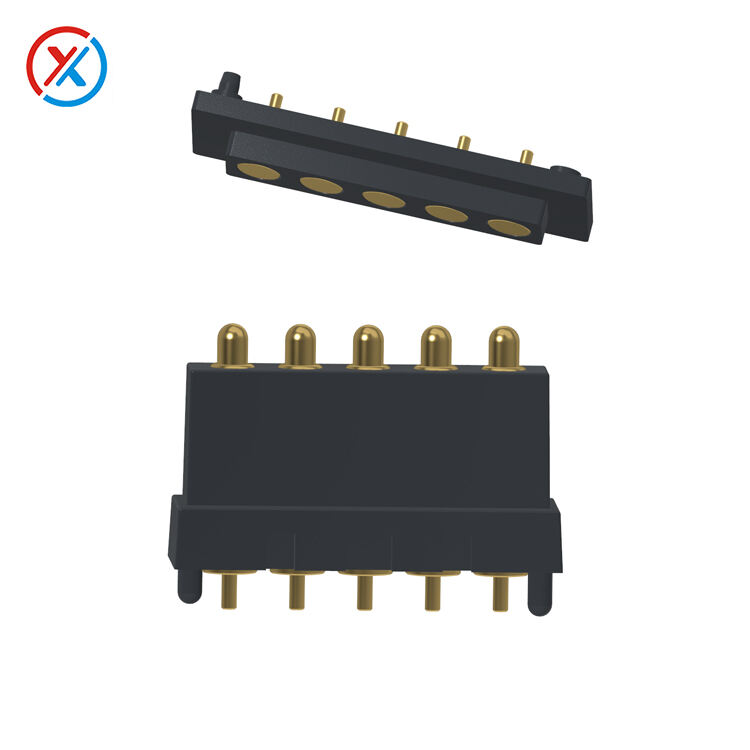

| This is a 2-4PIN Pogo pin connector that can be applied to sports equipment, LED lights, cameras, smart robots, and more; | |

| ITEM | DATA #1 |

| Model | SC-2-4pin |

| Metallic materials | Brass C3604 |

| PIN electroplating | Plating 3u"Au |

| Work schedule | 1.0mm |

| Elastic force | 70g±20g |

| Housing | HTN |

| Contact resistance of spring pin | 50mOhm Max. |

| Rated voltage | 12V |

| Rated current | 3.0A |

| Mechanical life | 1000,000 cycle Min |

| Salt spray test | 48H-96H |

| Packing | PE bag / reel packing |

| Material and coating conform to ROHS and REACH standards | |

3、Pogo pin connector scheme can be customized according to your requirements.

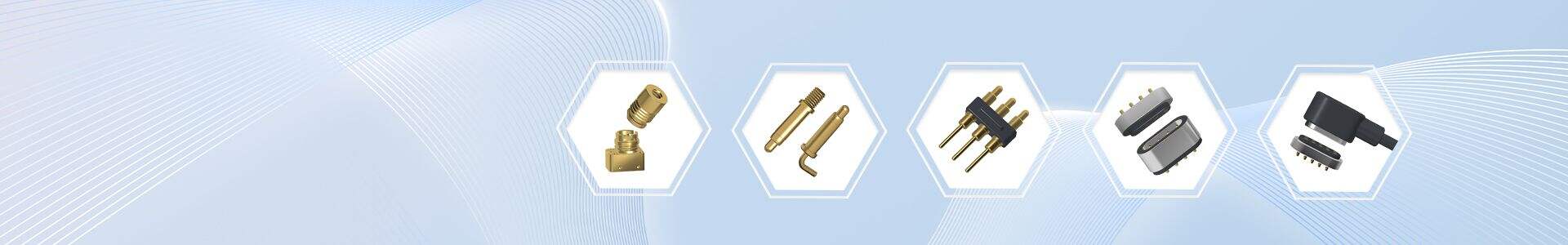

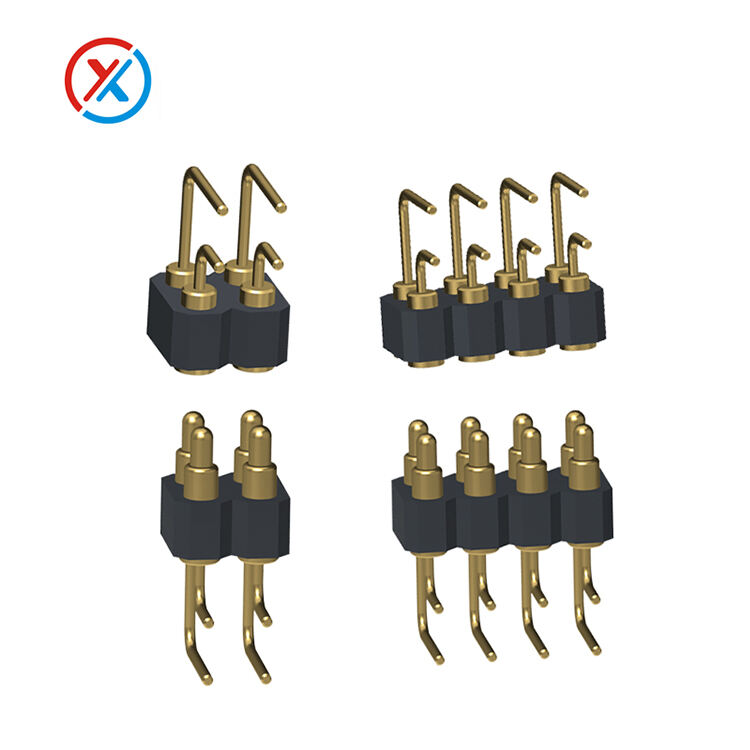

1. Shape structure: SMT,DIP, bend, double pin, welding wire structure, integrated type.

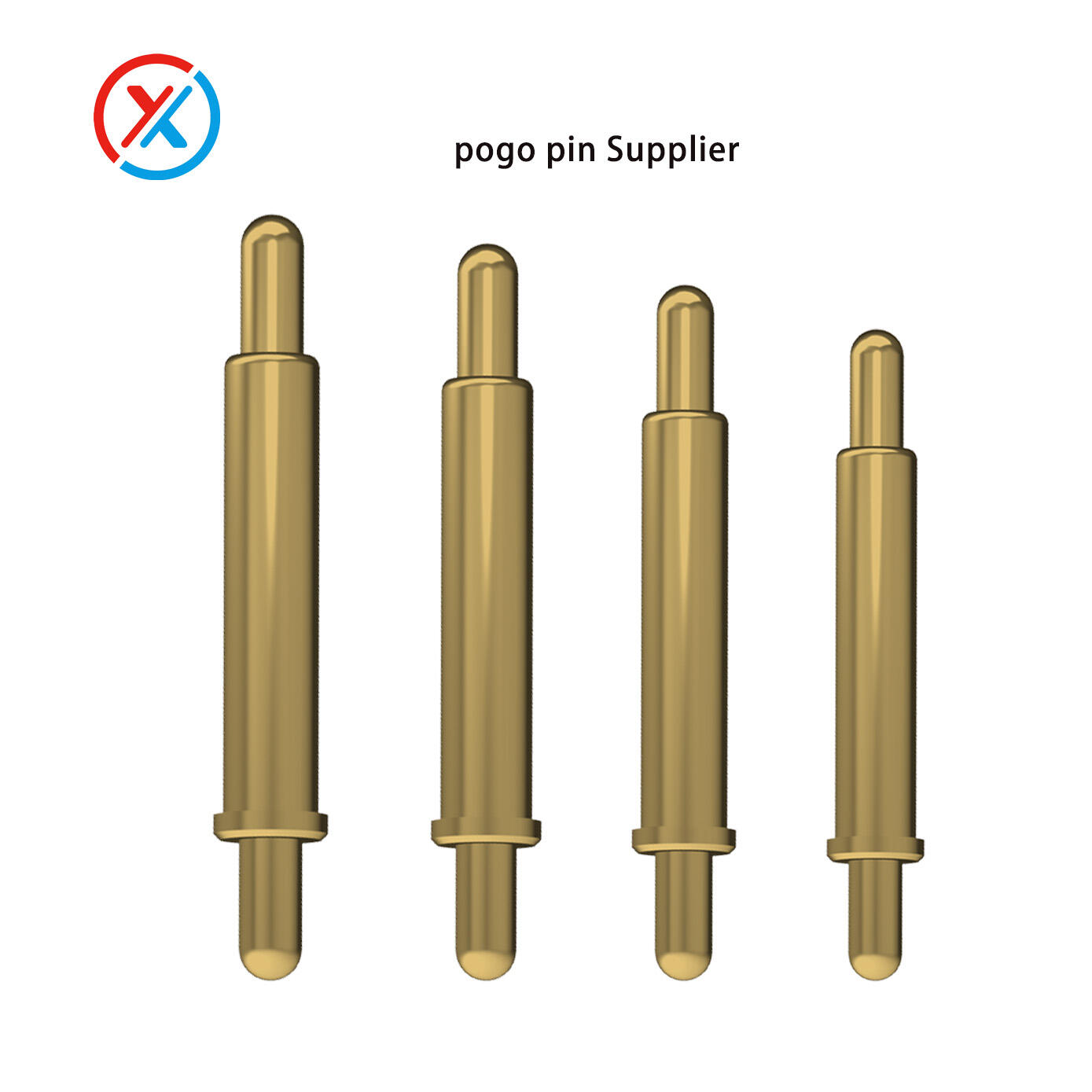

2. Material: C3604 C6801.

3. Elasticity: ≤ 15g.

4. Rated voltage / current: ≤ 120V, ≤ 40A.

5. Connection method: 90 °, 180 °or other angle.

6. Mother end assembly style; DIP, 90 °bending, welding wire, glue wrap molding, etc.

7. Mother end positioning mode: concave and convex groove, sealing ring, clamping lock, positioning ear, positioning column, in-mold injection molding.

Let us be your most reliable supplier!

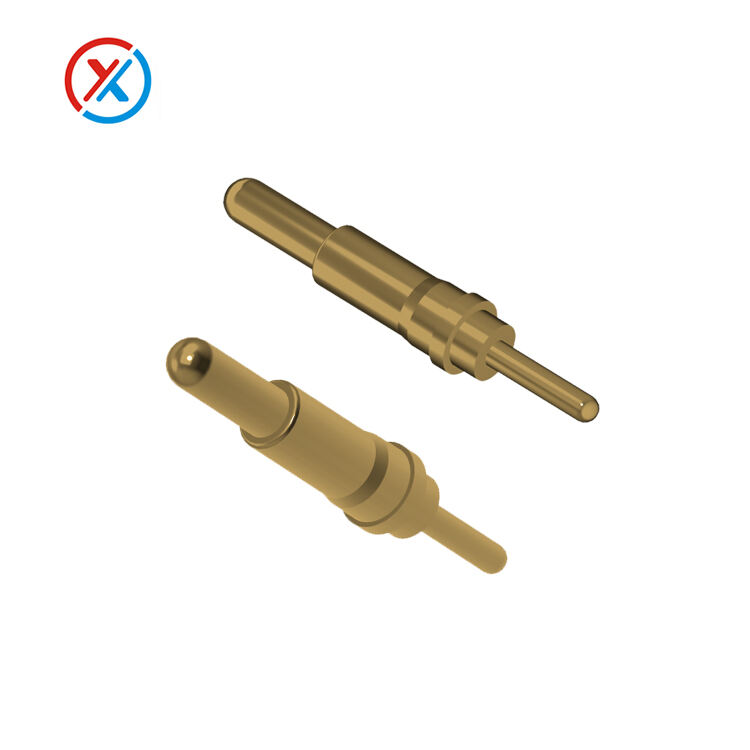

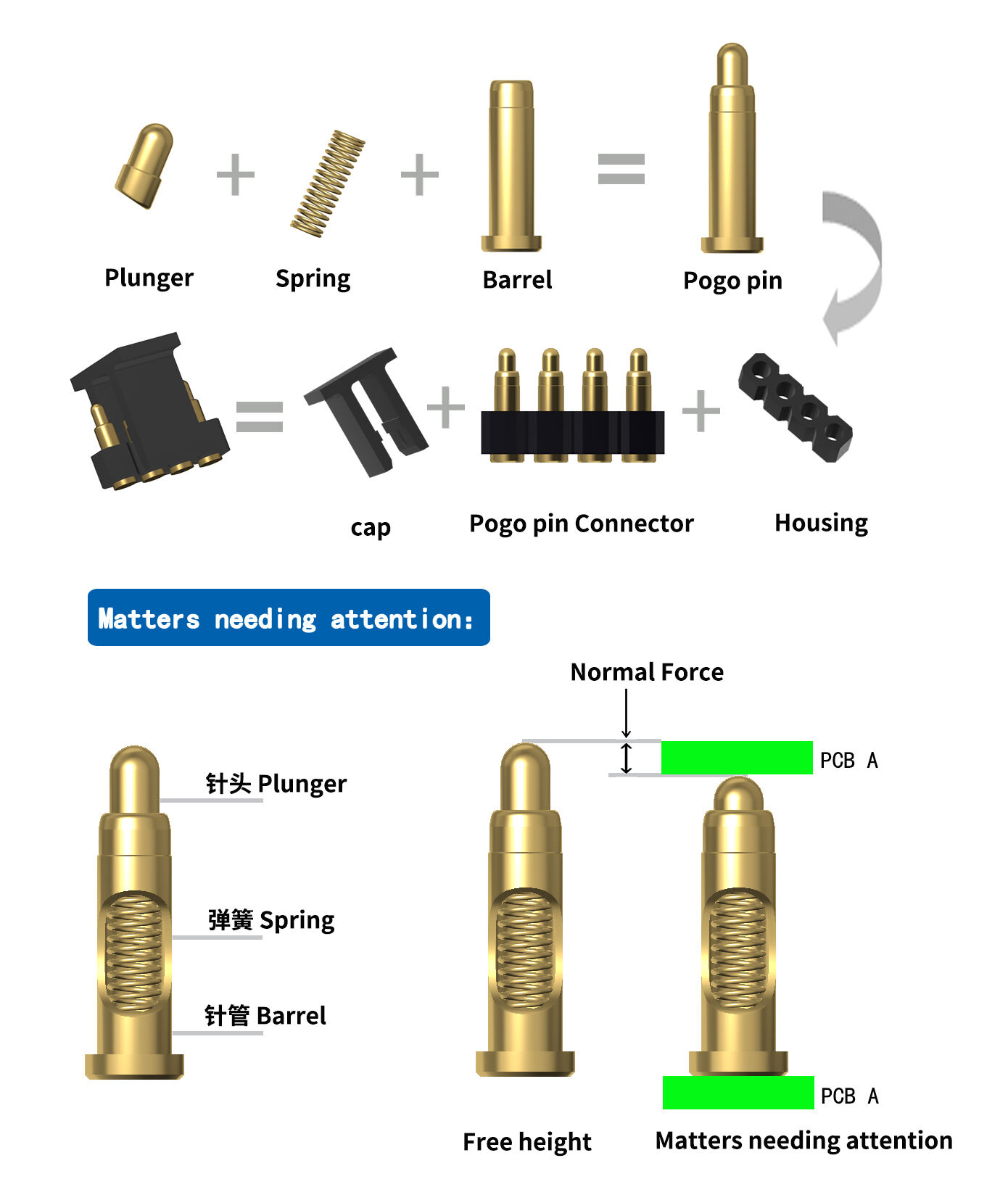

4、Introduction to Pogo pin Connector

POGO PIN is a spring-loaded probe made by riveting the three components of the needle shaft, spring and needle tube through precision equipment, also known as pogo pin, spring thimble, POGOPIN connector. The bottom of the needle of POGO PIN is usually a beveled structure, and the function of the beveled structure is to ensure that the POGO PIN keeps the needle in contact with the inner wall of the needle tube when working, so that the current mainly passes through the gold-plated needle and needle tube to ensure the stability and low impedance of POGO PIN;

*In the design, the compression amount is generally 2 inch 3 of the total stroke;too little pressure and insufficient forward force will lead to impedance instability;too much pressure will damage the pipe mouth and lead to poor card PIN.

*In the process of assembly, we should also pay attention to keep the pipe mouthaway from the force, so as not to hit the pipe mouth and cause PIN card.

*Battery contacts paired with POGOPIN or FPC gold fingers should not have dirt, oxidation, etc.

5、Product application display

6、Company introduction

Xinteng is a pogopin magnetic connector solution source factory, mainly produces pogopin, spring pin connectors, magnetic connectors, magnetic charging lines and other precision hardware; factory area of 2700 square meters, 12 R & D personnel, customized development products have 100 + items, obtained a national patent certificate of 40 million; at present, there are a variety of magnetic products to choose from, can also provide technical services for your product design and development, to relieve your worries.

7、Product category

Xinteng Electronics belongs to a pogopin magnetic connector solution source factory, from design-R & D-production, one-stop service; mainly produces pogopin, spring pin connectors, magnetic connectors, magnetic charging lines and other precision hardware; factory area of 2700 square meters, R & D staff of 12 people, customized development products have 600 + items, obtained national patent certificate 80 +. At present, there are a variety of magnetic products to choose from, and it can also provide technical services for your product design and development to relieve your worries.

Hope to further communicate the details, to facilitate the rapid provision of products, thank you!

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

SR

SR

UK

UK

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

SW

SW

GA

GA

CY

CY

IS

IS

BN

BN

BS

BS

NE

NE