- Overview

- Parameter

- Inquiry

- Related Products

2、Product parameters:

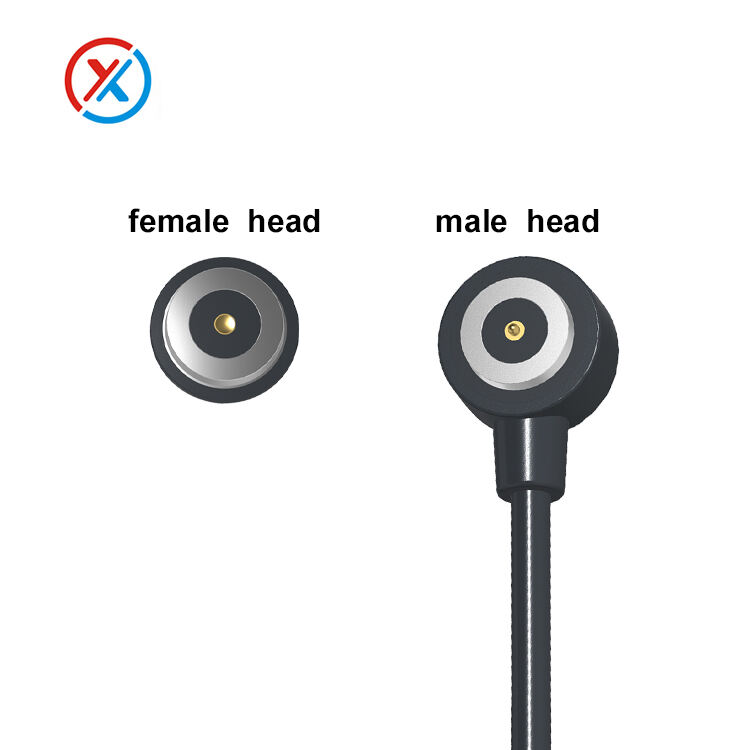

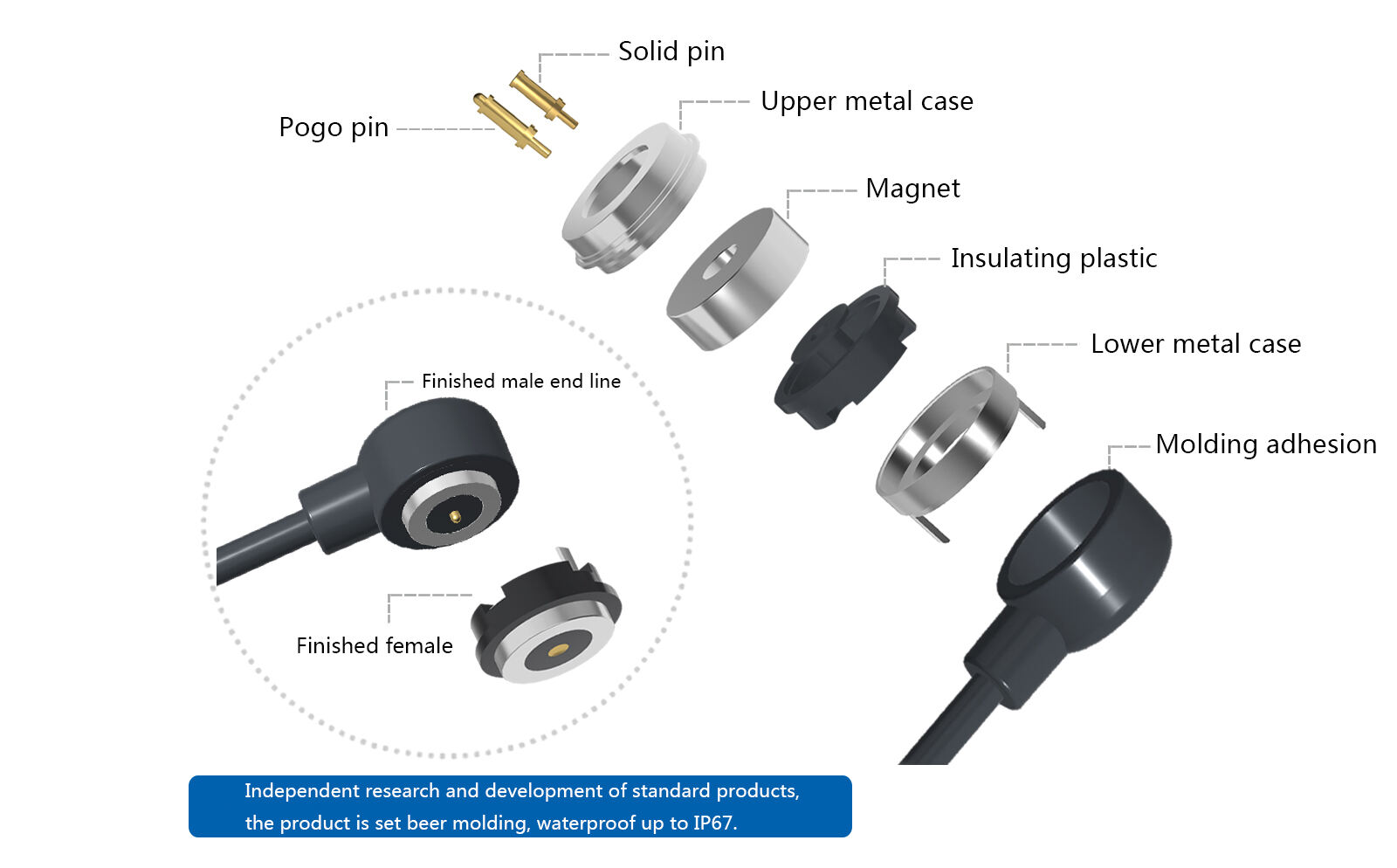

| This is a Φ10MM Round magnetic connector male and female seat, female head can reach waterproof IP67, can be used in: Medical, LED lights, Security, Handheld terminal,3C Consumer and so on. | |

| ITEM | DATA #1 |

| Model | SC-400 |

| Metallic materials | Brass C6801 |

| PIN electroplating | Au 0.125um~0.75um |

| Housing | HTN |

| Magnet | N52 |

| Contact resistance of spring pin | 50mOhm Max. |

| Rated voltage | 12V |

| Rated current | 3.0A |

| Mechanical life | 10,000 cycle Min |

| Salt spray test | 48H |

| Suction force | 650g±20% |

| Packing | Bubble cotton |

| Material and coating conform to ROHS and REACH standards | |

3、Pogo pin magnetic cable can be customized according to your requirements.

1. Shape and structure: round, square, long strip, runway, etc.

2. Wire materials: PVC, TPE, silica gel, etc.

3. Wire shape: round wire, braided wire, flat wire, etc.

4. Waterproof grade: up to IP68.

5. Suction: 150g-3000g.

6. Rated voltage / current: ≤ 120V, ≤ 40A.

7. Connection method: 90 °, 180 °or other angle.

8. Replacement ability: Ihammer O adapter, USB2.0/3.0, HDMI, RJ45, D-SUB, pin busbar, DC Jack, etc.

9. Mother end assembly style; DIP, 90 °bending, welding wire, glue wrap molding, etc.

10. Mother end positioning mode: concave and convex groove, sealing ring, clamping lock, positioning ear, positioning column, in-mold injection molding.

Let us be your most reliable supplier!

4、Introduction to Pogo pin Magnetic data cable

The magnetic data cable is composed of spring needle magnetic connector and connecting cable, which is an optimized upgrade scheme based on the traditional charging + data signal transmission applications such as Imax O, Micro- Usb, Type-C, HDMI, RJ45 and so on. The magnetic data cable is also called magnetic charging cable, magnetic charging cable and so on. The parts are composed of Pogo pin, plastic, magnet (Fe-Ni alloy), wire and so on. It really realizes 100% automatic positioning, automatic connection, fast insertion and unplugging, external force separation, and forced disconnection that will not damage the connection port of the equipment. It has been rapidly promoted and applied in many fields.

5、Product application display

The application areas of circular high-current magnetic connectors are diverse and span across numerous industries. Here is a detailed list of the primary sectors where these connectors are extensively utilized:

1. Electronic Devices

- Smartphones, Tablets, Laptops: These devices represent a common application area for circular high-current magnetic connectors. The magnetic connection enhances charging convenience while ensuring stable data transmission. Their capability to support high currents facilitates rapid charging, enhancing user experience.

- Wearable Devices: Such as smartwatches and health monitoring devices, which require connectors that are both convenient and reliable. Circular high-current magnetic connectors fulfill these requirements seamlessly.

2. Automotive Industry

- In-Car Chargers and Data Cable Connectors: Within automobiles, these connectors are widely used for in-car chargers and data cable connectors. They offer stable power and data transmission while enhancing usability and safety through magnetic connection.

- Electric Vehicle Charging: As electric vehicles gain popularity, circular high-current magnetic connectors play a vital role in their charging infrastructure. They support high-power charging, enabling electric vehicles to recharge quickly.

3. Medical Equipment

- Portable Monitoring Devices: In the medical field, these connectors are used for devices that require quick replacement or removal. They provide a safe, reliable, and easy-to-operate connection method, assisting medical personnel in swiftly completing device changes and maintenance.

- High-Power Medical Devices: Some high-powered medical equipment also relies on circular high-current magnetic connectors to ensure stable and safe power supply.

4. Industrial Applications

- Machinery and Devices: In mechanical setups requiring swift tool or component changes, these connectors offer an efficient and reliable connection method. They significantly increase production efficiency by reducing downtime associated with tool or component replacement.

- Automated Production Lines: On automated production lines, circular high-current magnetic connectors are used to connect various devices and sensors. They facilitate rapid and stable signal and power transmission, ensuring smooth line operation.

5. Other Fields

- Smart Homes: With the development of smart homes, these connectors are also being incorporated into some smart home devices. They achieve stable connections between devices and power sources or control centers through magnetic connection.

- Aerospace: In the aerospace industry, circular high-current magnetic connectors play a crucial role in connecting electronic equipment and sensors, ensuring the proper operation and data transmission of aircraft.

In summary, circular high-current magnetic connectors, with their unique advantages, have found widespread applications in electronic devices, the automotive industry, medical equipment, industrial applications, and various other sectors. As technology continues to evolve and innovate, their scope of application is expected to further expand.

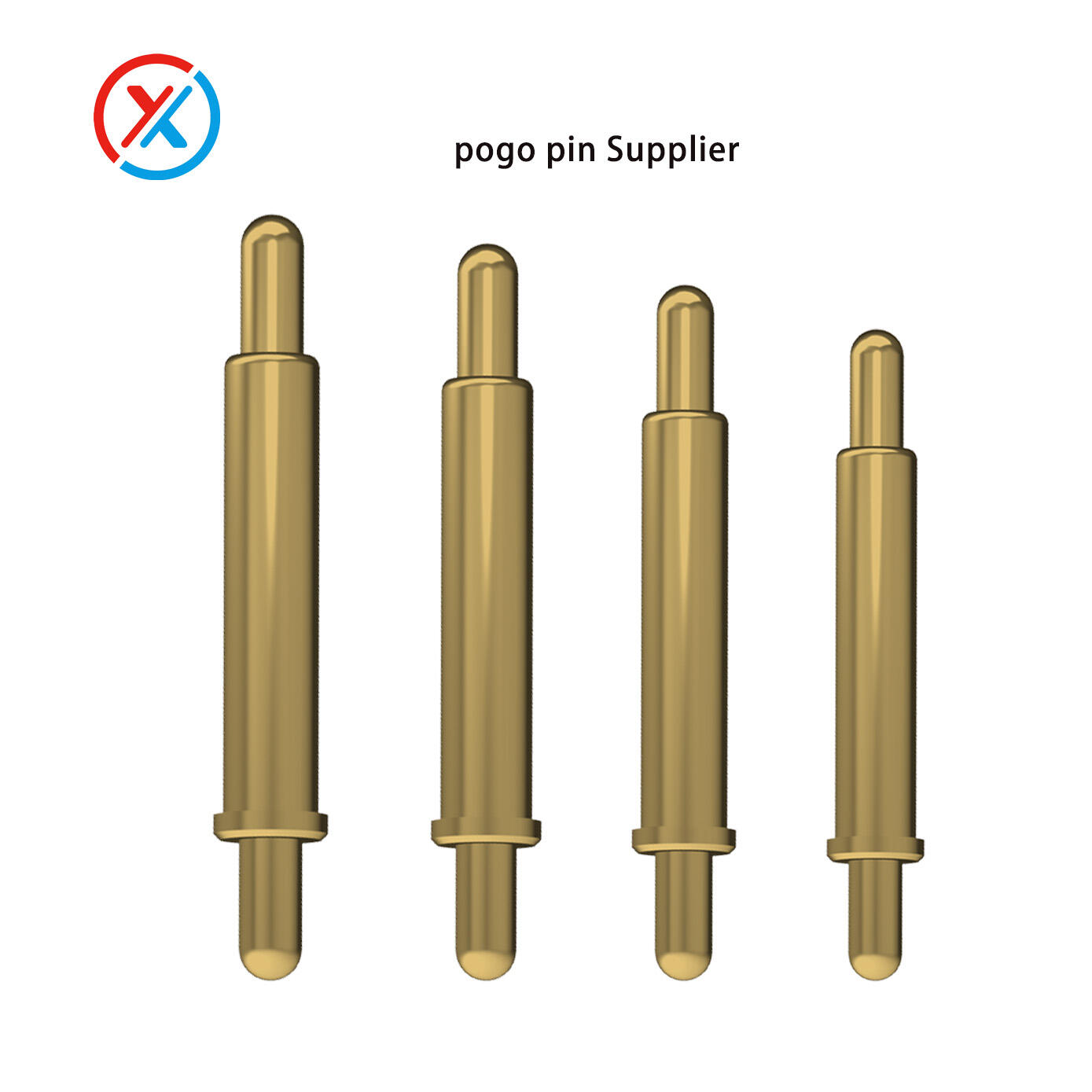

6、Company introduction

Xinteng is a pogopin magnetic connector solution source factory, mainly produces pogopin, spring pin connectors, magnetic connectors, magnetic charging lines and other precision hardware; factory area of 2700 square meters, 12 R & D personnel, customized development products have 100 + items, obtained a national patent certificate of 40 million; at present, there are a variety of magnetic products to choose from, can also provide technical services for your product design and development, to relieve your worries.

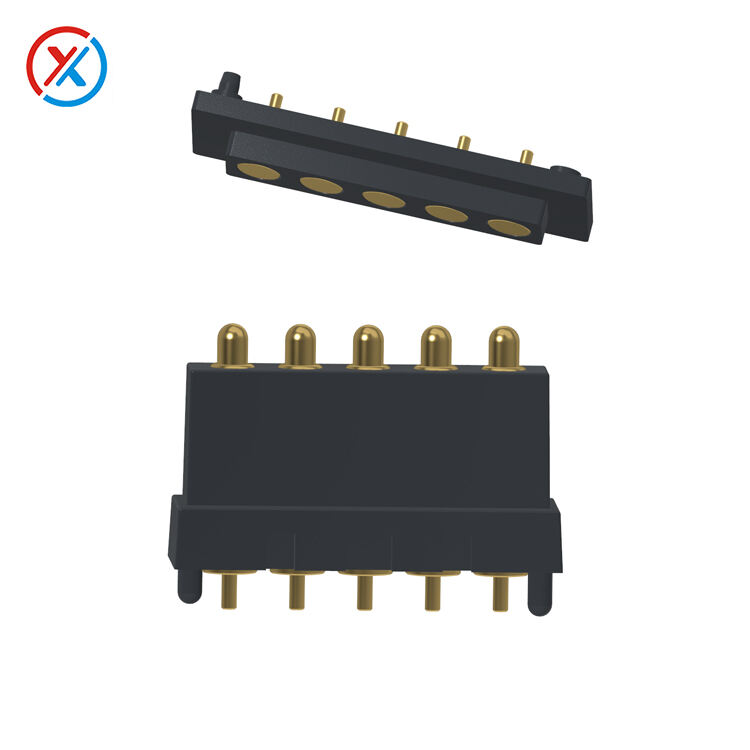

7、Product category

Xinteng Electronics belongs to a pogopin magnetic connector solution source factory, from design-R & D-production, one-stop service; mainly produces pogopin, spring pin connectors, magnetic connectors, magnetic charging lines and other precision hardware; factory area of 2700 square meters, R & D staff of 12 people, customized development products have 600 + items, obtained national patent certificate 80 +. At present, there are a variety of magnetic products to choose from, and it can also provide technical services for your product design and development to relieve your worries.

Hope to further communicate the details, to facilitate the rapid provision of products, thank you!

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

SR

SR

UK

UK

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

SW

SW

GA

GA

CY

CY

IS

IS

BN

BN

BS

BS

NE

NE