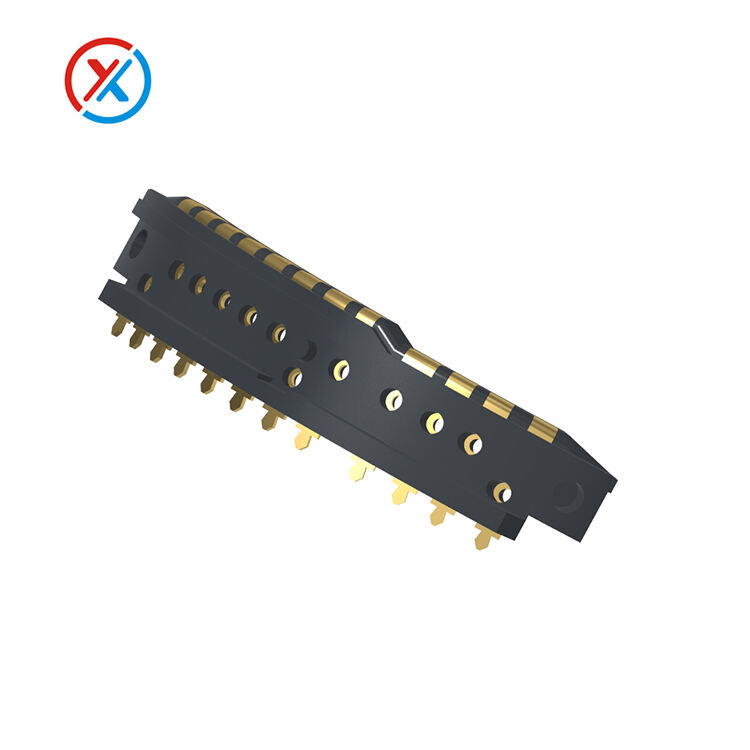

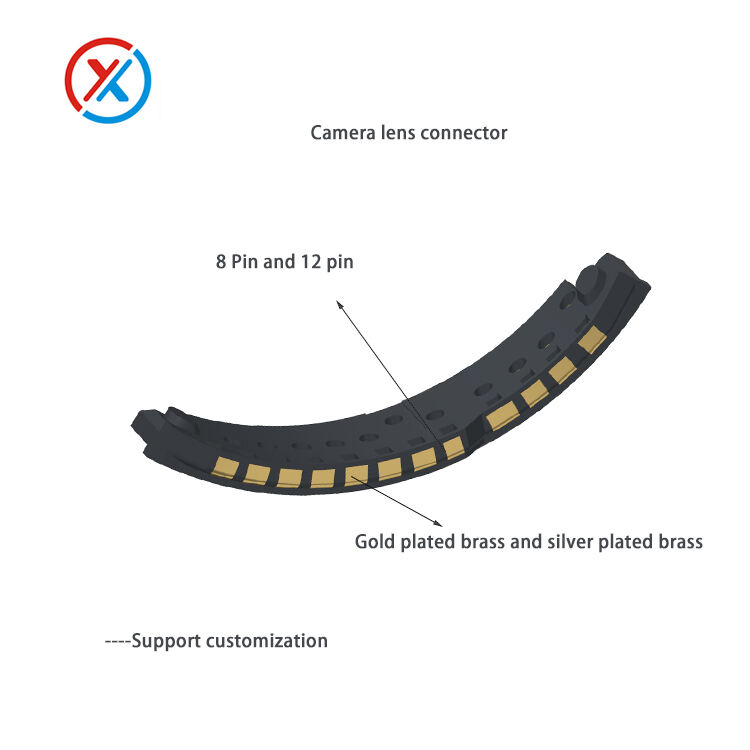

Camera lens contact connector manufacturer,Camera lens connector 8 pin brass gilding-118

Product Name:pogo connector-188

Product model:pogo connector-188

Delivery time: 15-20 days

- Overview

- Inquiry

- Related Products

1、Product features:

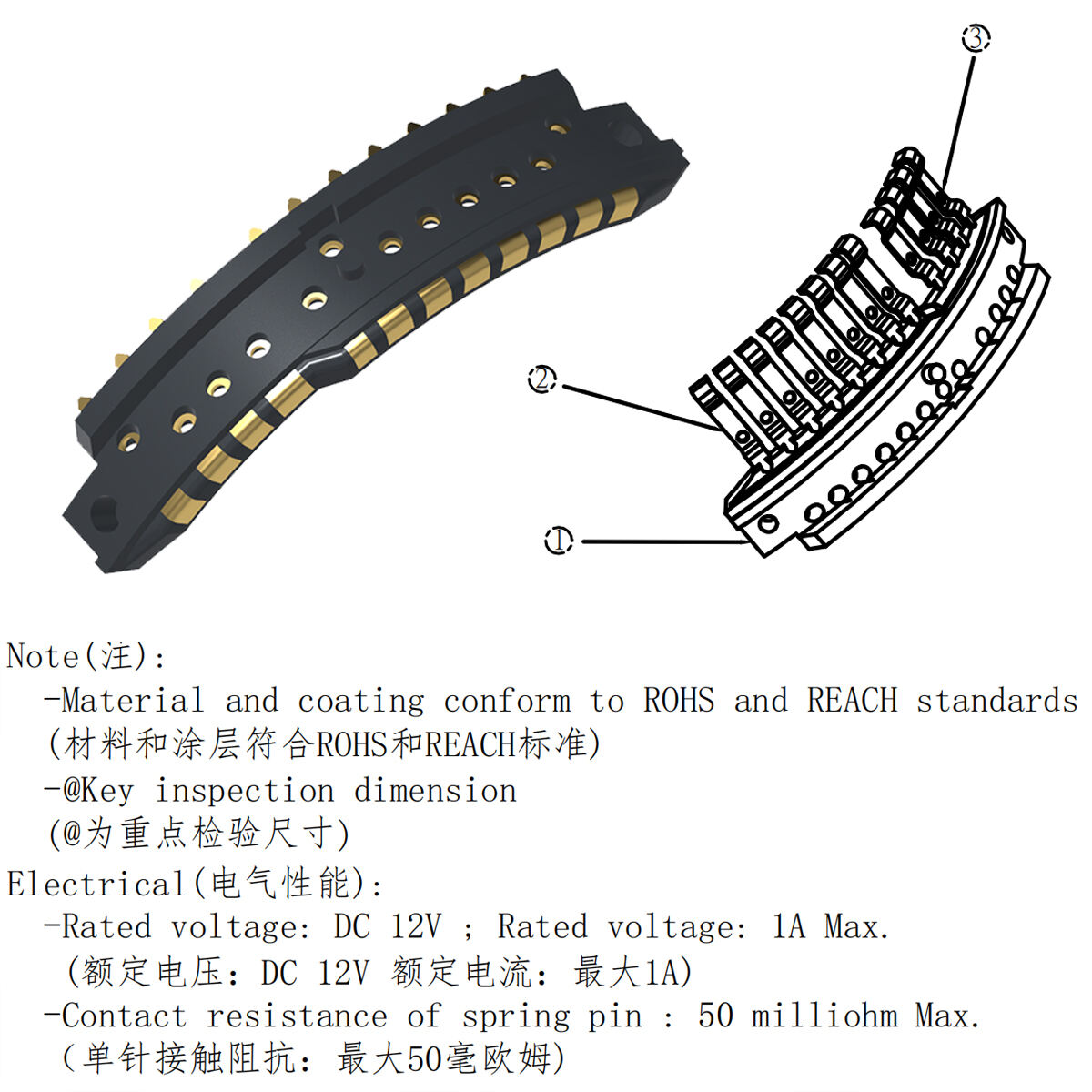

1)100% environmentally friendly materials that meet RoHs and REACH requirements.

2)Automatic riveting press assembly, automatic inspection and shipment.

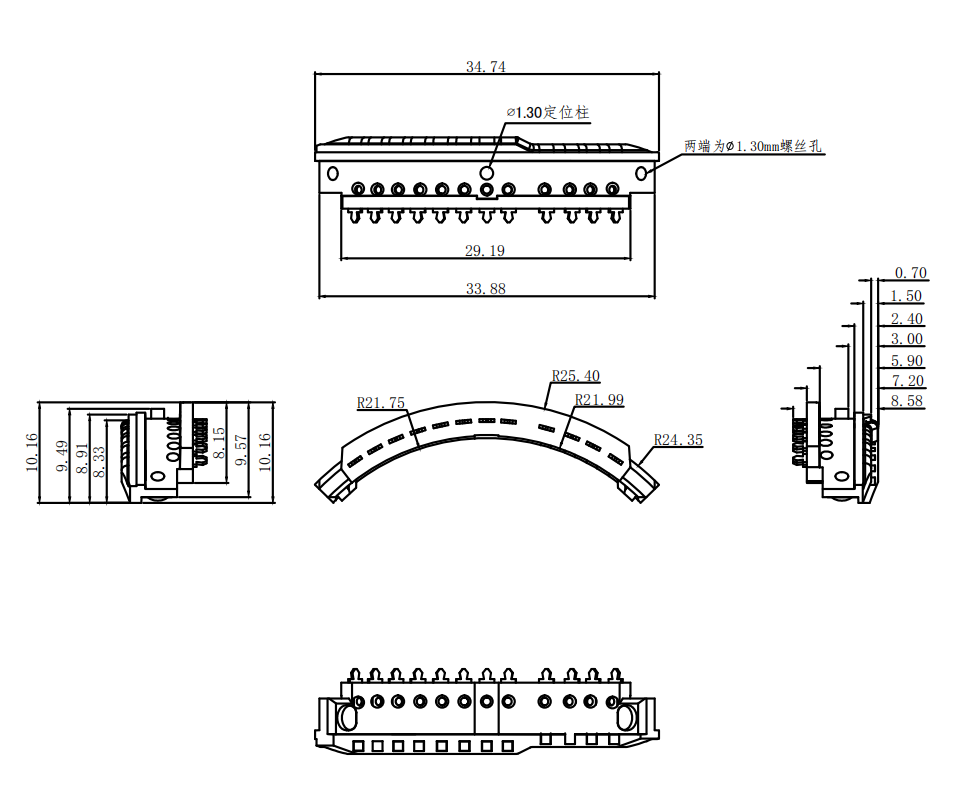

3)Tolerances can be controlled to ±0.01mm.

4)Contact impedance ≤ 15m Ω.

5)The life span can reach more than 1000000 times.

6)No mold opening, convenient customization, cost saving.

7)The elasticity can be adjusted according to the requirements.

8)Small spacing and space saving.

2、Product parameters:

| Camera lens contact connector, 8 pin 12 pin can be gold or silver plated, support custom shape and pin number | |

| ITEM | DATA #1 |

| Model | 8 pin 12 pin |

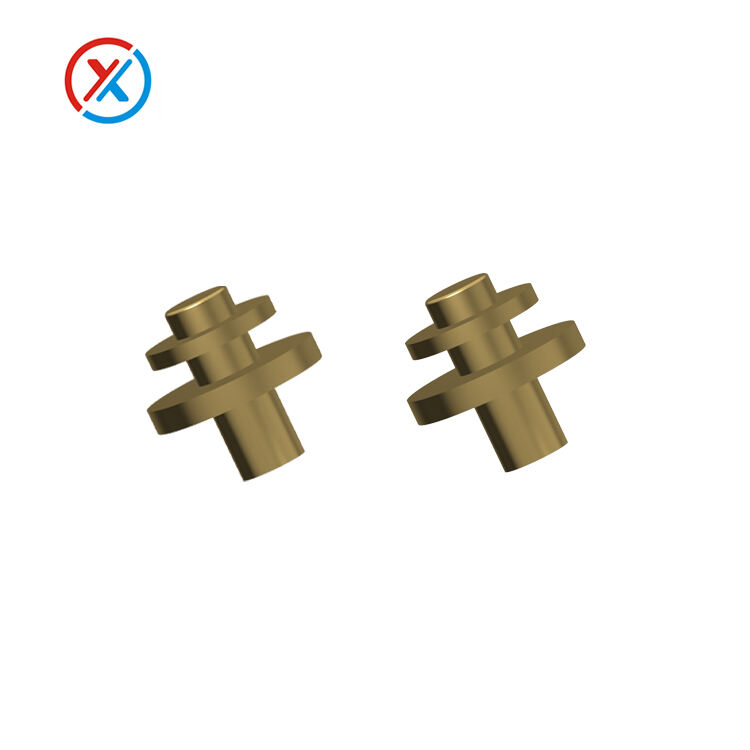

| Metallic materials | Brass C6801 |

| PIN electroplating | Plating 3u"Au |

| Work schedule | / |

| Elastic force | / |

| Housing | HTN |

| Contact resistance of spring pin | 50mOhm Max. |

| Rated voltage | 12V |

| Rated current | 1.0A |

| Mechanical life | / |

| Salt spray test | 48H-96H |

| Packing | PE bag / reel packing |

| Material and coating conform to ROHS and REACH standards | |

3、Pogo pin connector scheme can be customized according to your requirements.

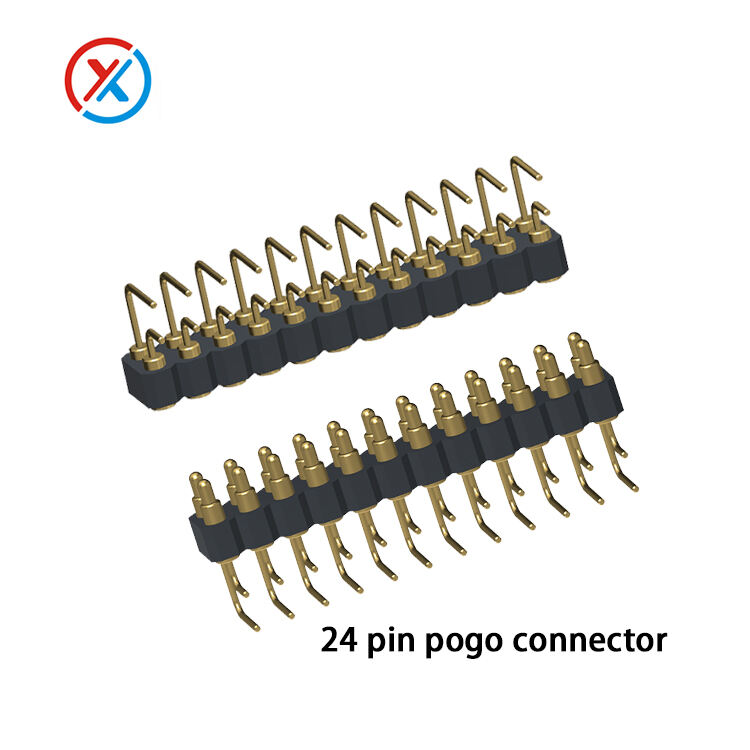

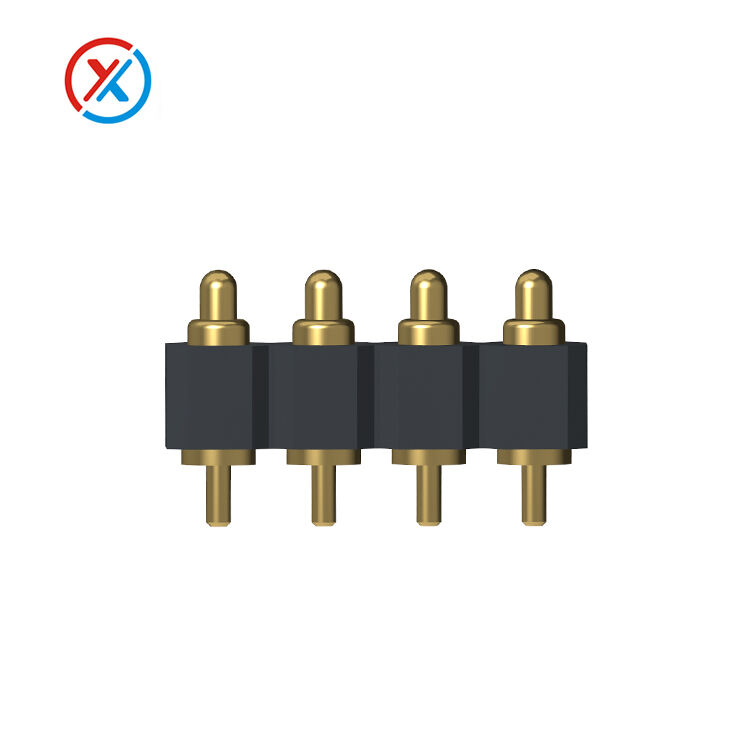

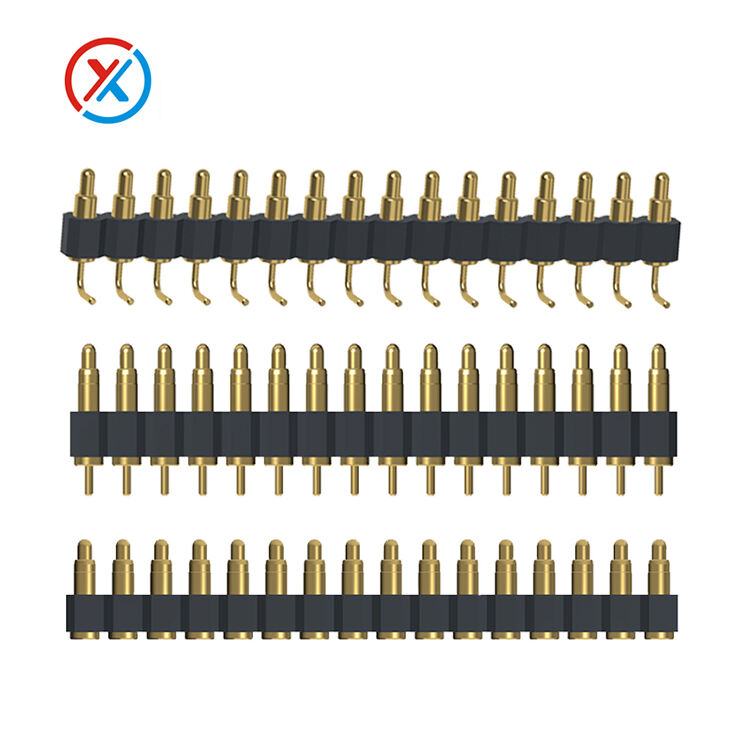

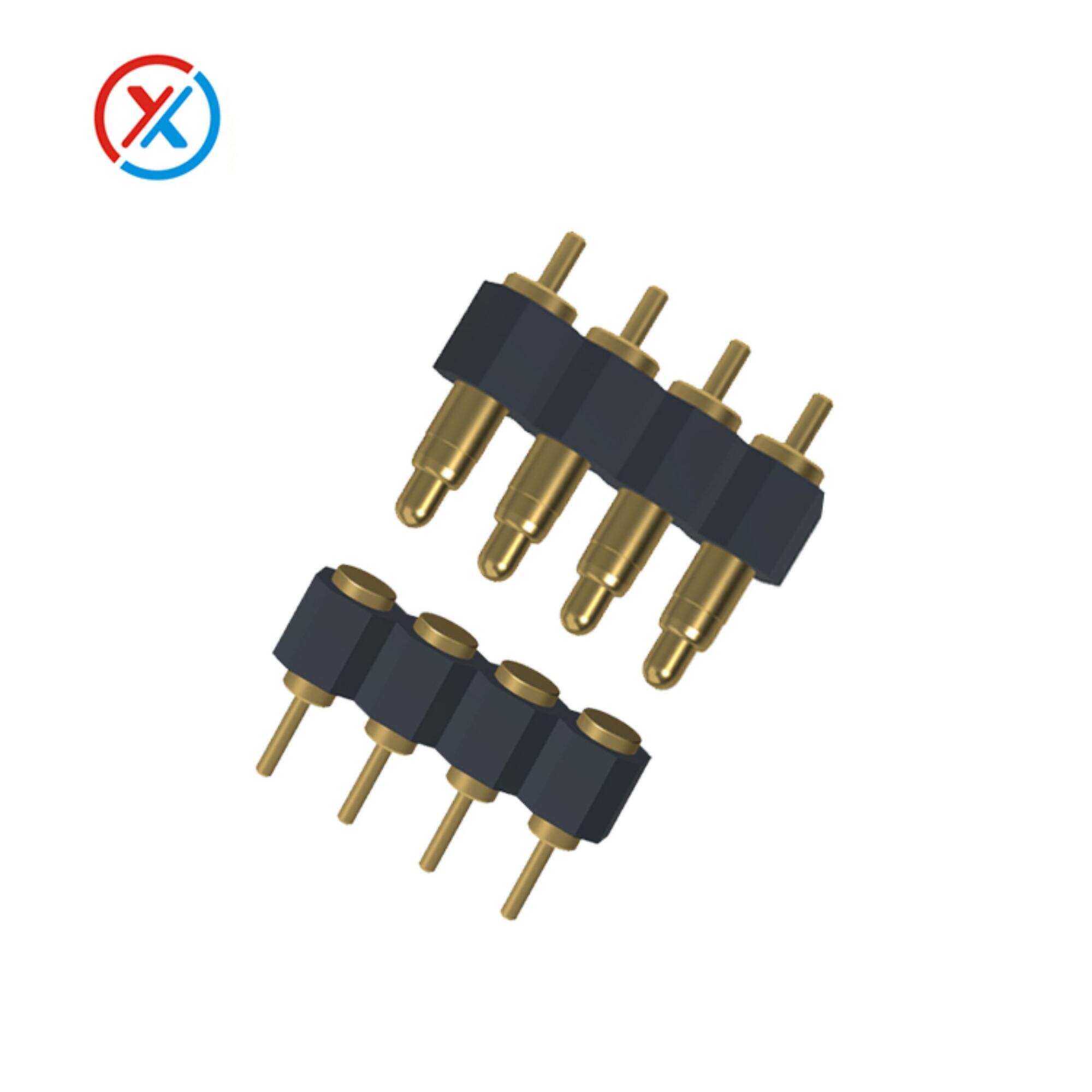

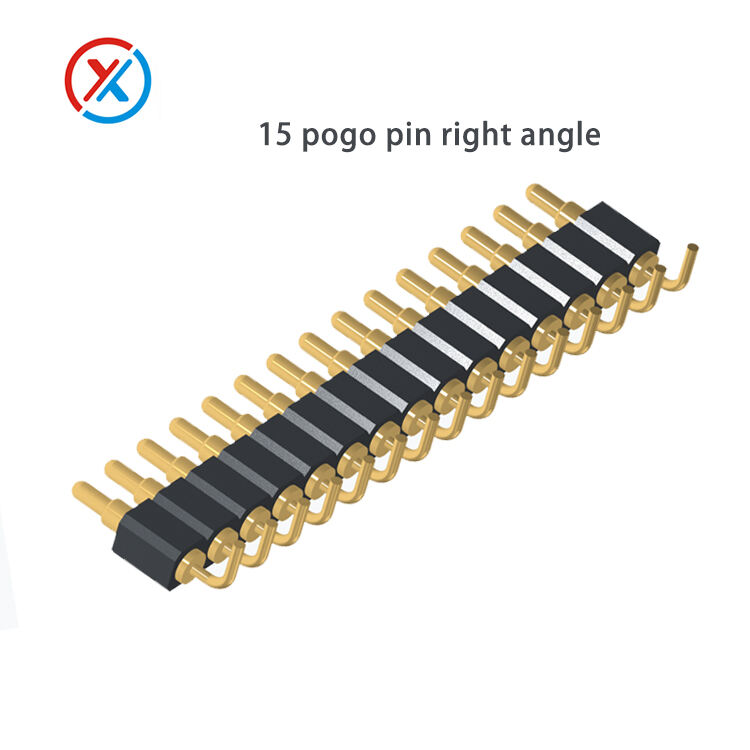

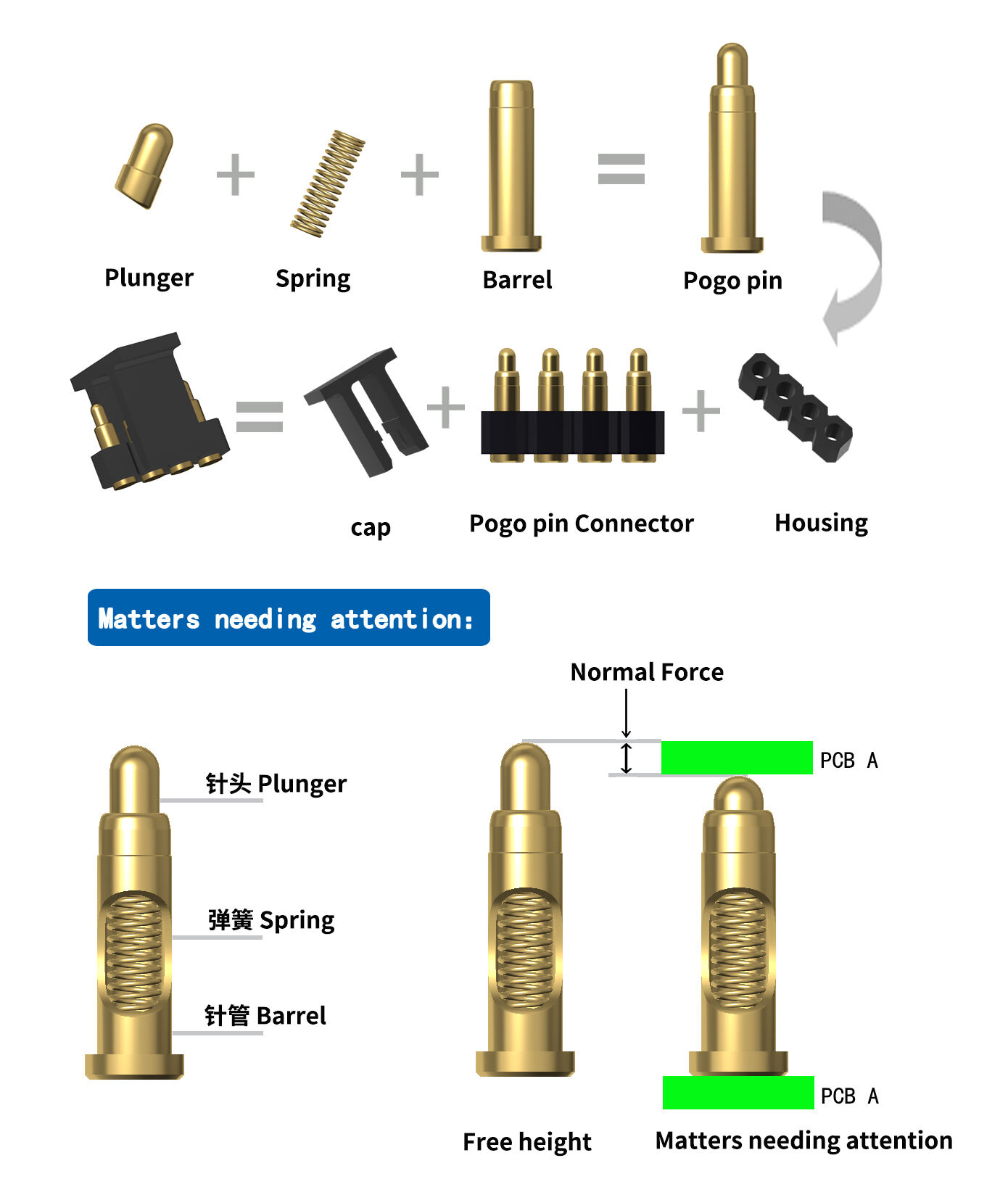

1. Shape structure: SMT,DIP, bend, double pin, welding wire structure, integrated type.

2. Material: C3604 C6801.

3. Elasticity: ≤ 15g.

4. Rated voltage / current: ≤ 120V, ≤ 40A.

5. Connection method: 90 °, 180 °or other angle.

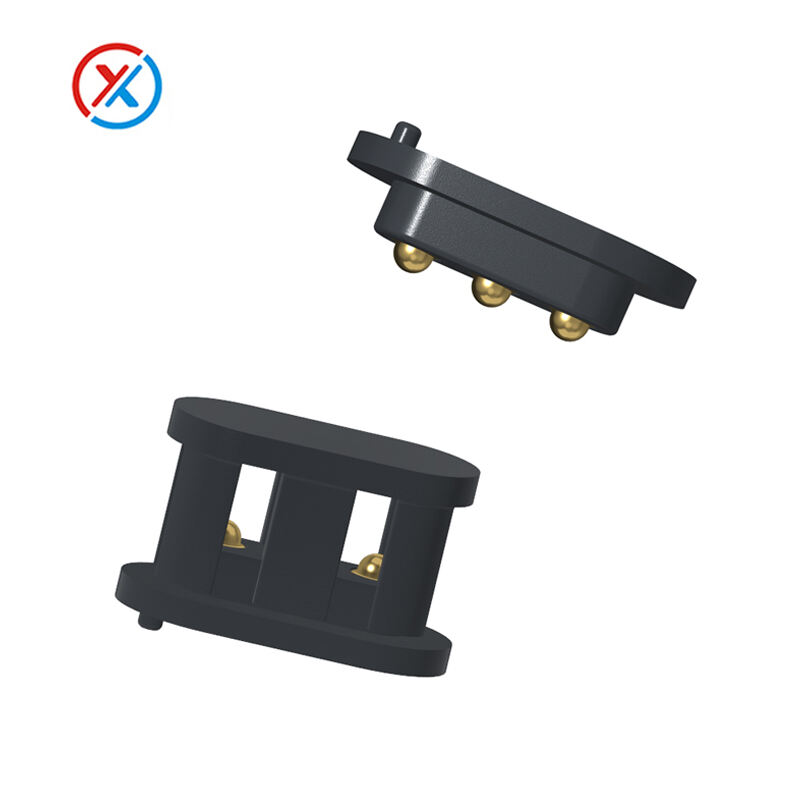

6. Mother end assembly style; DIP, 90 °bending, welding wire, glue wrap molding, etc.

7. Mother end positioning mode: concave and convex groove, sealing ring, clamping lock, positioning ear, positioning column, in-mold injection molding.

Let us be your most reliable supplier!

4、Features of camera lens connectors

High precision butt joint

Micrometer accuracy: The connector must have extremely high precision to ensure perfect docking between the lens and the body. This includes alignment of optical elements and accurate contact of electronic contacts.

Multi-point contact: Usually contains multiple contacts to transmit different signals, such as image data, autofocus commands, aperture control, etc.

2. Reliable electrical connection

Low contact resistance: The contact design of the connector ensures low contact resistance to reduce loss during signal transmission, ensuring image quality and normal operation of the function.

Corrosion-resistant materials: Contacts are usually made of gold-plated or other corrosion-resistant materials to extend service life and maintain long-term electrical performance.

3. Mechanical strength

Durability: Connectors need to be able to withstand frequent insertion and removal operations and are usually designed to withstand thousands of insertions or more.

Resistance to vibration and shock: The camera may be subject to vibration and shock during shooting, and the connector needs to have sufficient mechanical strength to maintain a stable connection.

4. Dust and water proof

Sealed design: Many high-end camera lens connectors are dustproof and waterproof, which prevents dust and moisture from entering through a sealed design, improving the reliability of the camera in harsh environments.

O-rings and gaskets: Use O-rings and gaskets around the connector to further enhance the seal.

5. Quick connection and disconnection

Plug and play: Users can quickly and easily change lenses without complicated tools or steps.

Locking mechanism: Most lens connectors are equipped with a locking mechanism to ensure that the lens does not accidentally fall off during use.

6. Versatility

Multiple signal transmission: In addition to optical signals, the connector also needs to transmit a variety of electronic signals, such as autofocus, aperture control, image stabilization, and lens information.

Compatibility: Different brands and models of cameras may use different lens connectors, but lenses and bodies within the same brand usually have good compatibility.

7. Miniaturization and lightweight

Compact design: Connectors are usually designed to be very compact to accommodate the small structure of cameras and lenses.

Lightweight materials: Use lightweight materials such as aluminum alloys and engineering plastics to reduce overall weight.

5、pogo pin connector composition

6、Company introduction

Xinteng Electronics belongs to a pogopin magnetic connector solution source factory, from design-R & D-production, one-stop service; mainly produces pogopin, spring pin connectors, magnetic connectors, magnetic charging lines and other precision hardware; factory area of 2700 square meters, R & D staff of 12 people, customized development products have 600 + items, obtained national patent certificate 80 +. At present, there are a variety of magnetic products to choose from, and it can also provide technical services for your product design and development to relieve your worries.

7、Product category

Xinteng company produces pogo pins, pogo pin connectors, magnetic connectors, magnetic data lines and other products. It is used for charging, data transmission or connection between internal components in consumer electronics industry, smart wearable, smart home appliances, medical beauty, Internet of Things equipment, drone equipment and other industries

Hope to further communicate the details, to facilitate the rapid provision of products, thank you!

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

SR

SR

UK

UK

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

SW

SW

GA

GA

CY

CY

IS

IS

BN

BN

BS

BS

NE

NE