- Overview

- Inquiry

- Related Products

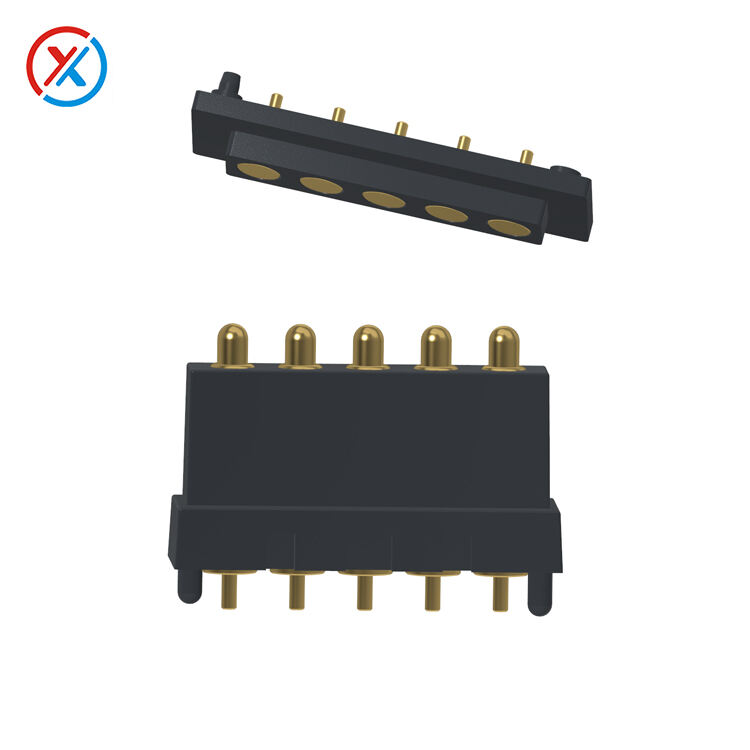

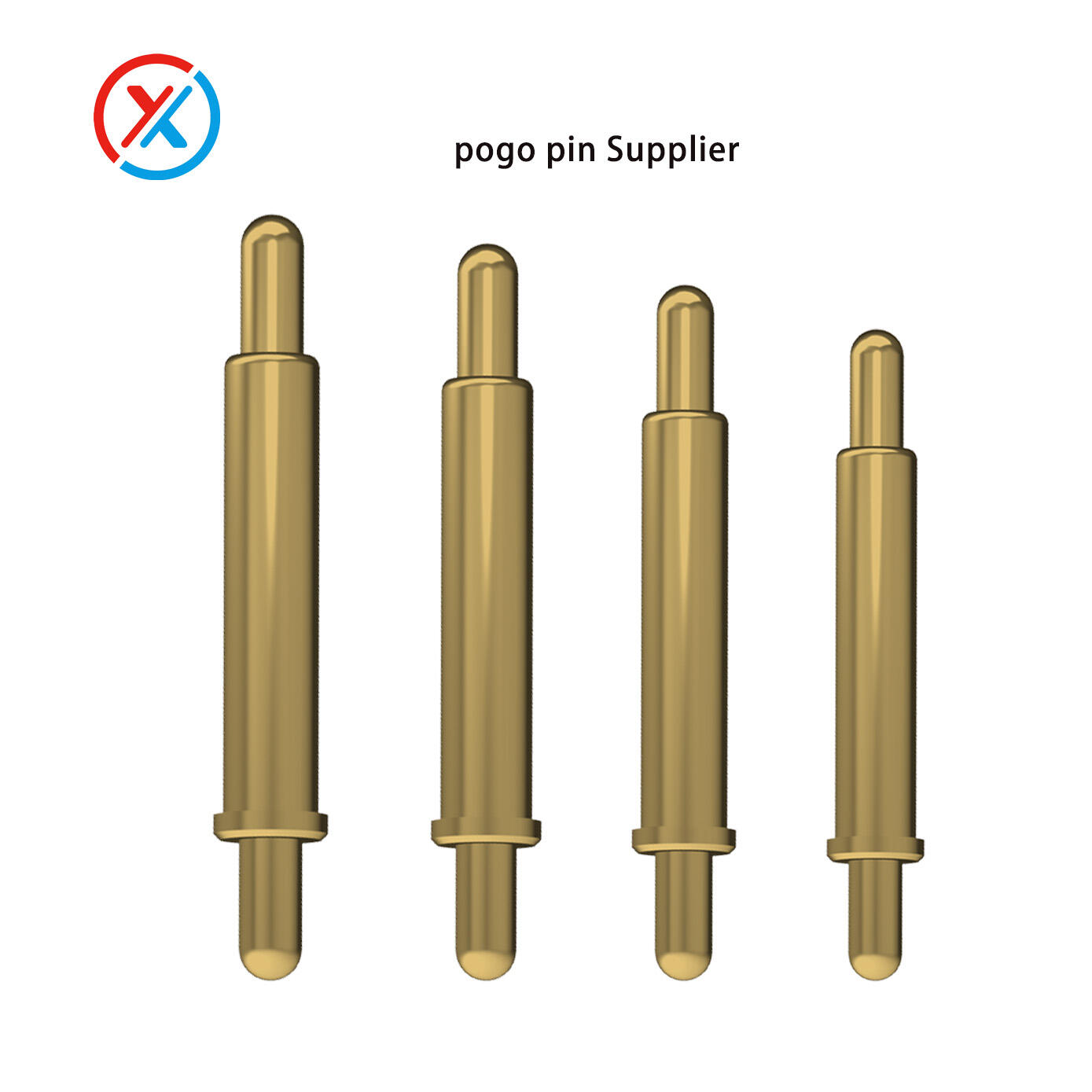

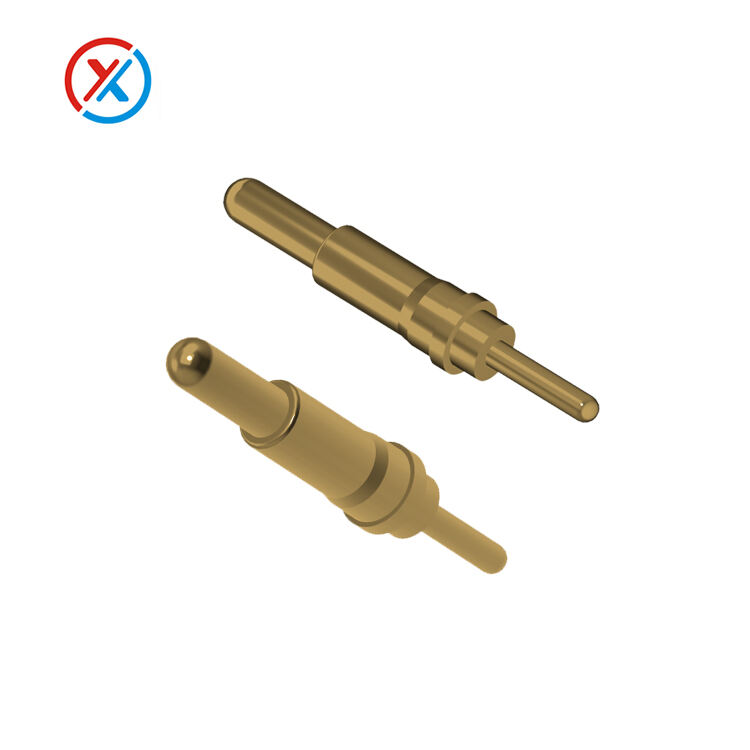

1.30A high-current welding wire POGO PINS connector

Designed for high-power equipment, our solder-based pogo pins feature 30A ultra-high current carrying capacity, combined with precision construction and industrial durability to provide reliable power transmission solutions for high-end industrial, automotive and medical equipment.

Certification and compliance: Through RoHS, REACH, ISO 9001 certification, materials in line with EU environmental standards, support SGS test reports

Certification and compliance: Through RoHS, REACH, ISO 9001 certification, materials in line with EU environmental standards, support SGS test reports

Fast response and delivery: Vertically integrated production line, sample delivery in 3-5 days, mass production cycle reduced to 7-15 days, global logistics support

Fast response and delivery: Vertically integrated production line, sample delivery in 3-5 days, mass production cycle reduced to 7-15 days, global logistics support

Technical support: Free failure analysis and solution optimization, CNAS laboratories support full performance testing to ensure product integration without risk

Technical support: Free failure analysis and solution optimization, CNAS laboratories support full performance testing to ensure product integration without risk

2、Core feature

Ultra-large current support: The use of penetration pin shaft design, direct conduction of current, to avoid the risk of instantaneous interruption, support up to 30A continuous current transmission, to meet the industrial automation equipment, new energy vehicle charging module and other high-power scenarios.

Welded wire structure advantages: the spring foot tail adopts welded wire design, ADAPTS to CABLE end welding, flexibly responds to complex space layout, and is suitable for cable connection and PCB board welding, improving installation efficiency.

Long life and compression resistance: Through the buffer spring and limit chute structure design, the mechanical life of more than 50,000 times, can withstand radial pressure, prevent the needle deformation or stuck, to ensure long-term stability.

High temperature and corrosion resistance: gold plated brass substrate, contact resistance as low as 30mΩ, salt spray test up to 96 hours, suitable for high temperature, high humidity or corrosive environment, such as outdoor energy equipment, medical disinfection environment.

Customized services: Support needle shape (pointed/round/knife type), coating thickening, plastic material (PA/LCP) customization, to meet the special needs of different industries for water, dust or impact resistance

3、What are the advantages of choosing our pogo pins

100% environmentally friendly materials that meet RoHs and REACH requirements.

100% environmentally friendly materials that meet RoHs and REACH requirements.

Automatic riveting press assembly, automatic inspection and shipment.

Automatic riveting press assembly, automatic inspection and shipment.

Tolerances can be controlled to ±0.01mm.

Tolerances can be controlled to ±0.01mm.

Contact impedance ≤ 15m Ω.

Contact impedance ≤ 15m Ω.

The life span can reach more than 1000000 times.

The life span can reach more than 1000000 times.

No mold opening, convenient customization, cost saving.

No mold opening, convenient customization, cost saving.

The elasticity can be adjusted according to the requirements.

The elasticity can be adjusted according to the requirements.

7-day flexible customized production cycle, simultaneous provision of EMC protection optimization solutions and failure analysis services, to help you build a zero-defect supply chain system at a lower overall cost. ISO-certified factory production, complete material reports, environmental certification and 3D drawings are provided with the goods to help customers quickly pass product compliance reviews.

7-day flexible customized production cycle, simultaneous provision of EMC protection optimization solutions and failure analysis services, to help you build a zero-defect supply chain system at a lower overall cost. ISO-certified factory production, complete material reports, environmental certification and 3D drawings are provided with the goods to help customers quickly pass product compliance reviews.

4、pogo pins parameters:

| ITEM | DATA #1 |

| Model | 1059 |

| Metallic materials | Brass C6801 |

| PIN electroplating | Plating 5u"Au over 60~100u" Ni. |

| Rated current |

30 A |

| Mechanical life | 50,000 cycle Min |

| Material and coating conform to ROHS and REACH standards | |

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

SR

SR

UK

UK

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

SW

SW

GA

GA

CY

CY

IS

IS

BN

BN

BS

BS

NE

NE