- Overview

- Parameter

- Inquiry

- Related Products

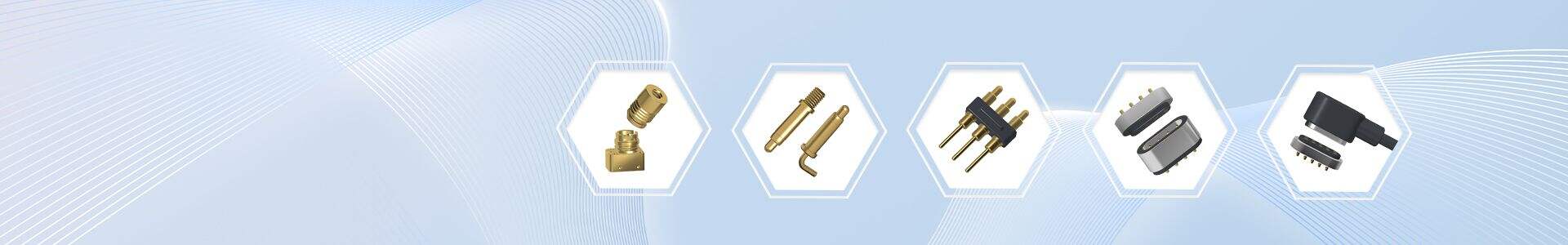

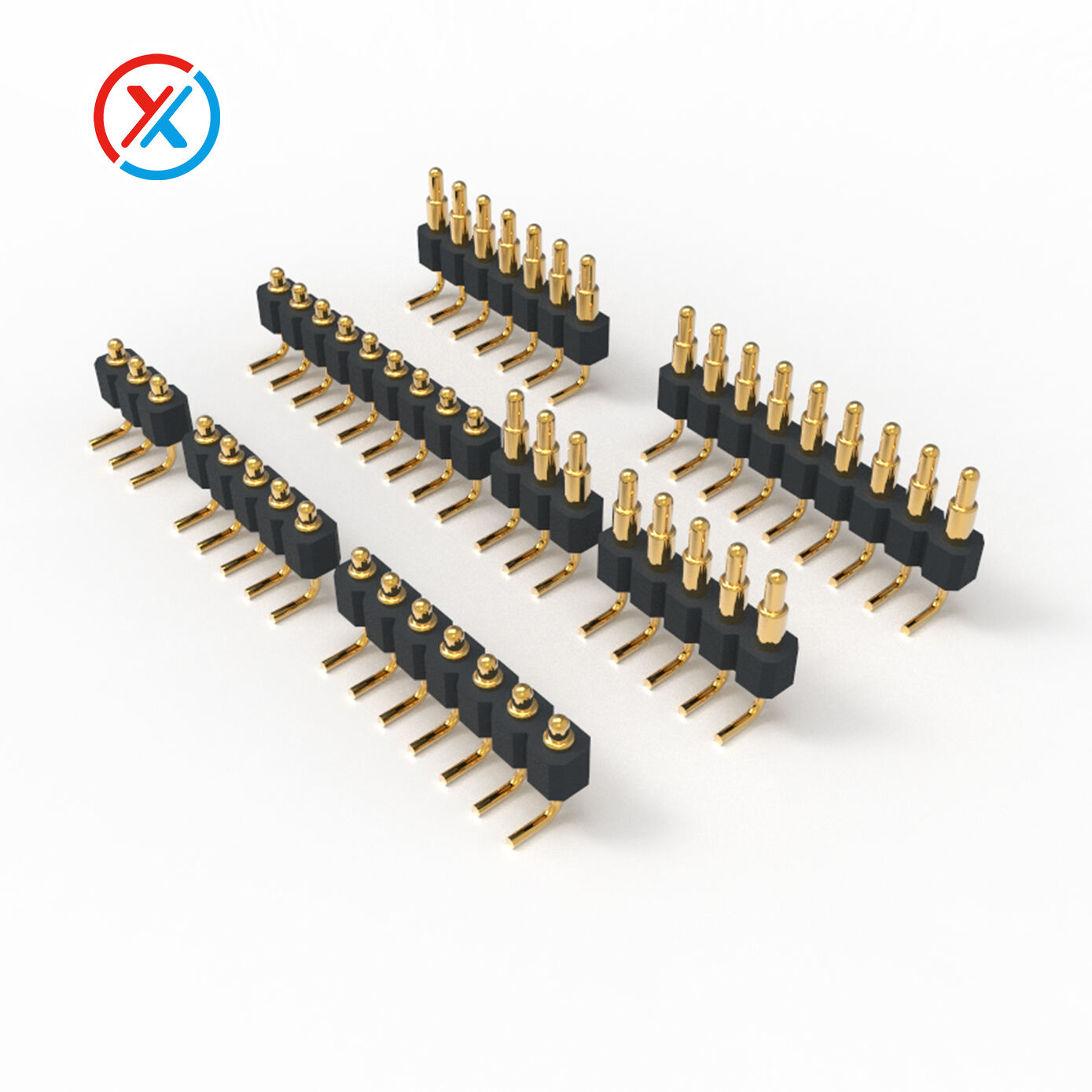

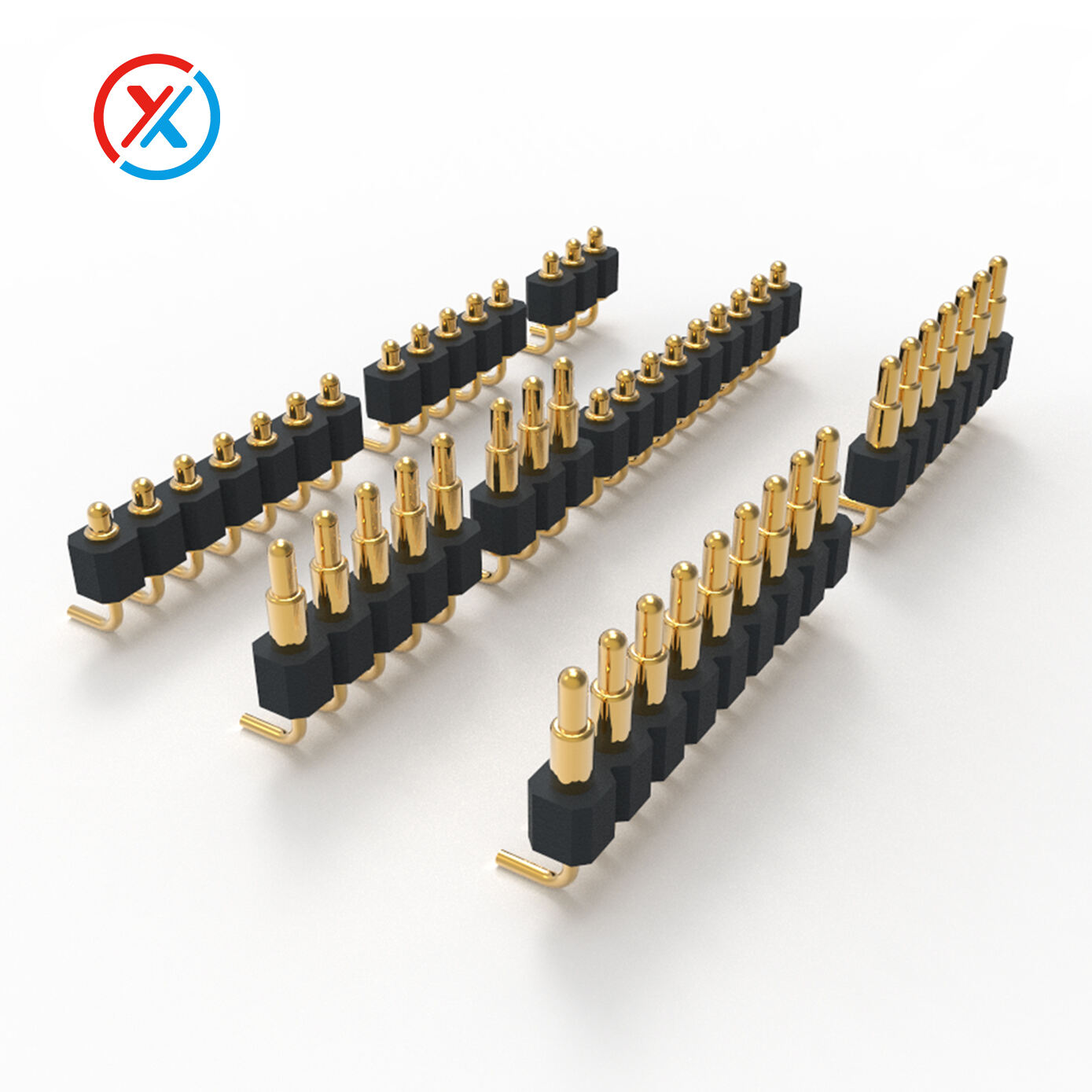

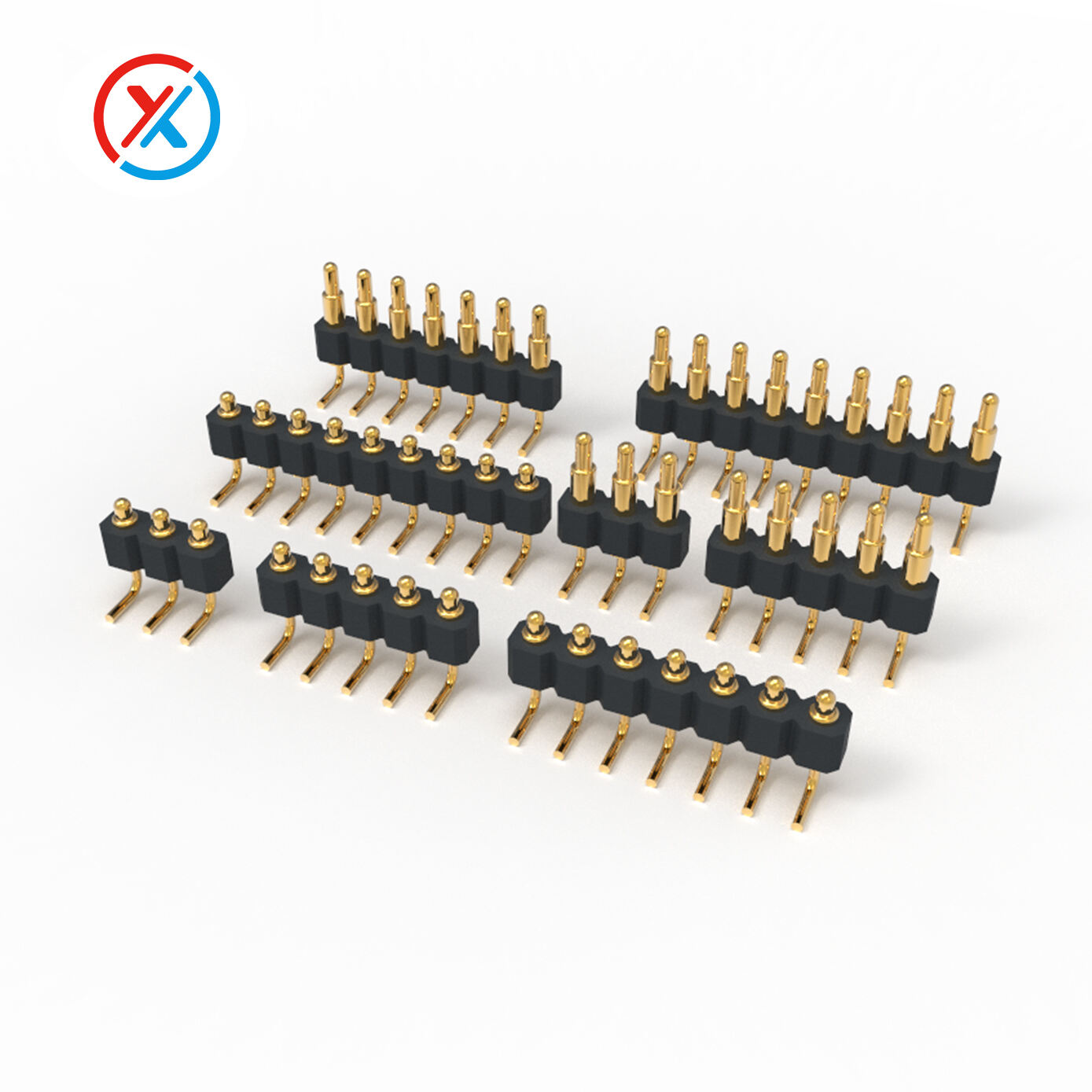

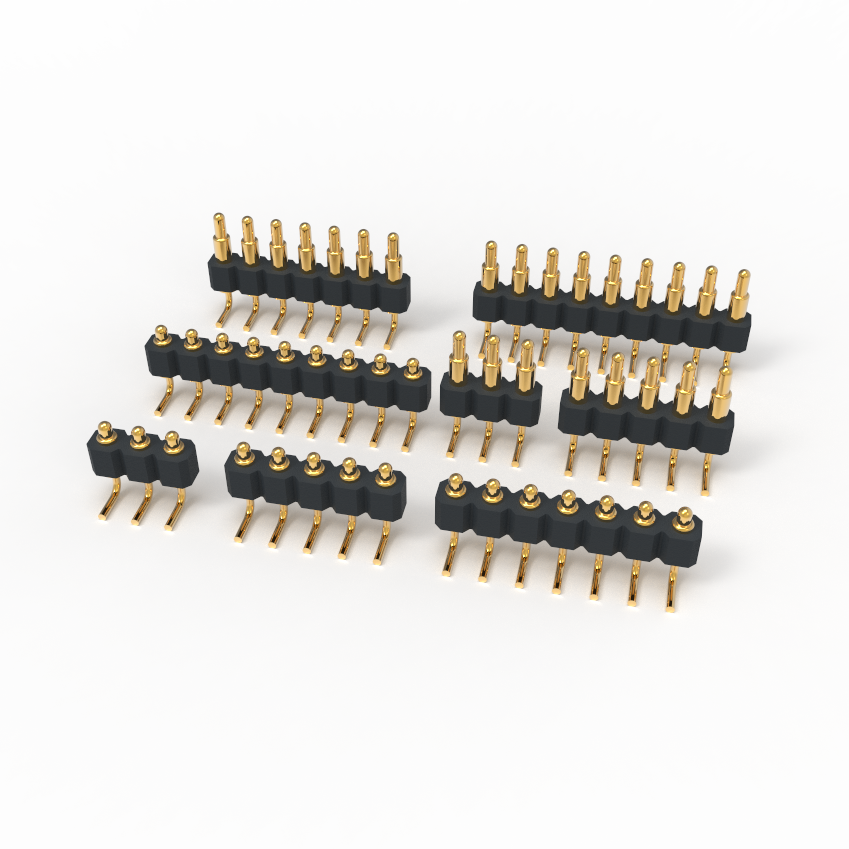

1、1-100 Pin Angled Pogo Pin Connectors Features :

Our customizable bendable Pogo Pin breaks through the space limitations of traditional connectors and supports 0°-360° arbitrary angle bending design. The height (3-50mm) and spacing (±0.1mm accuracy) can be adjusted as needed, perfectly adapting to complex structural scenarios such as micro medical equipment, industrial robot joint modules, and drone precision circuits. The contacts use a multi-layer gold plating process to ensure stable transmission of 1-20A current.

2、Product features:

1)100% environmentally friendly materials that meet RoHs and REACH requirements.

2)No mold opening, convenient customization, cost saving.

3)Tolerances can be controlled to ±0.01mm.

4)Contact impedance ≤ 15m Ω.

5)The life span can reach more than 1000000 times.

6)Automatic riveting press assembly, automatic inspection and shipment.

7)The elasticity can be adjusted according to the requirements.

8)Small spacing and space saving.

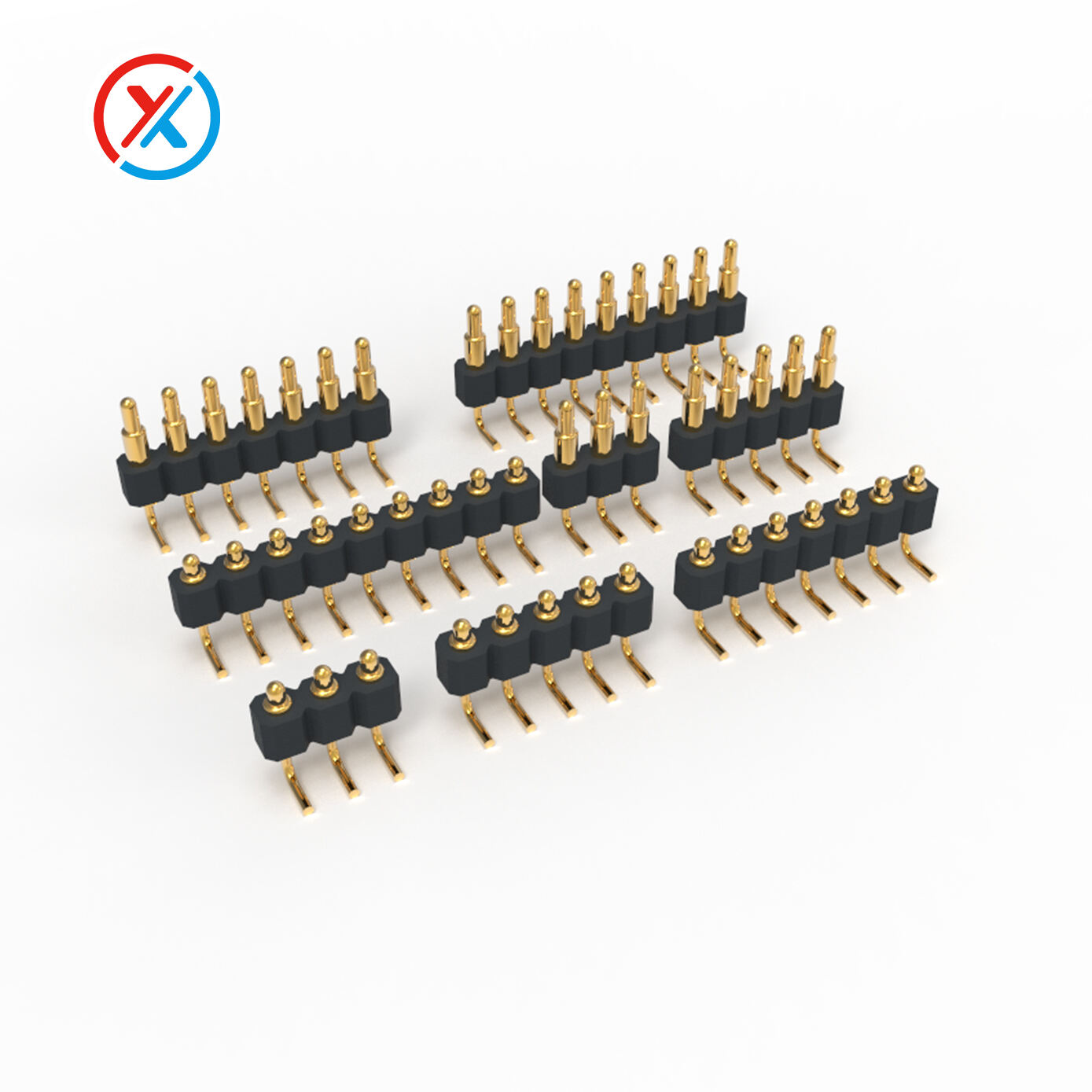

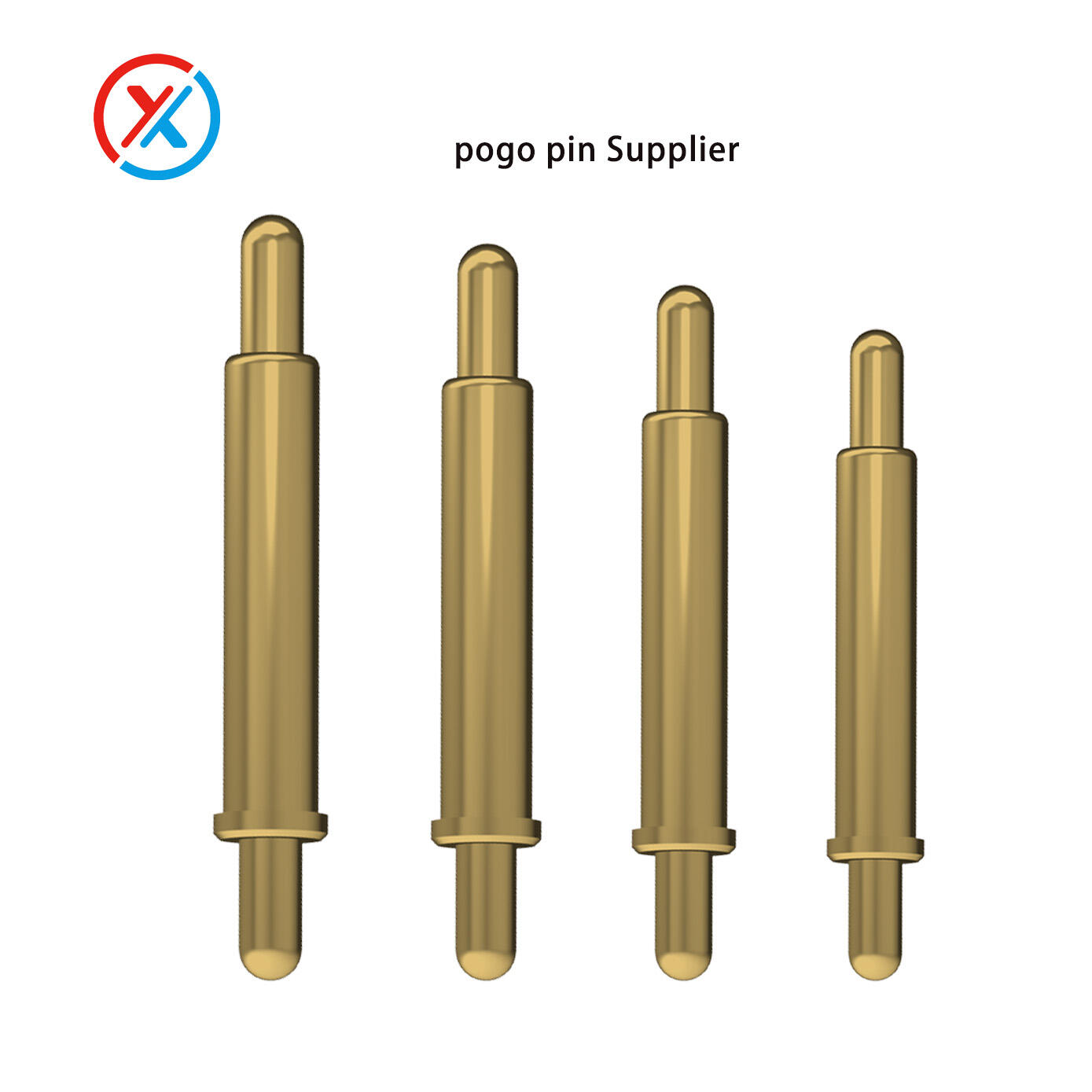

3、Product parameters:

| 1-100 pin angled pogo pin connectors, male and female pin connector China supplier | |

| ITEM | DATA #1 |

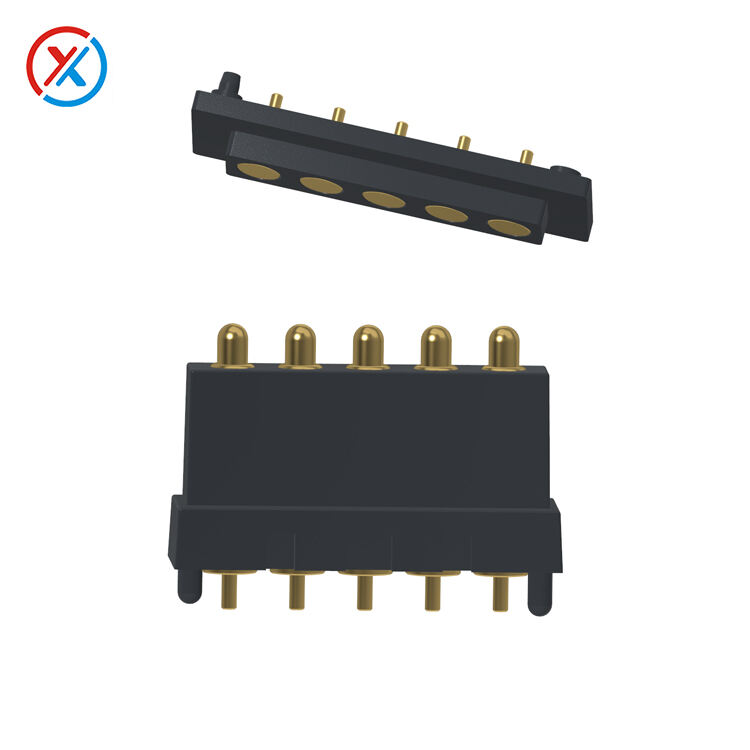

| Model | side-mounted |

| Metallic materials | Brass C6801 |

| PIN electroplating | Plating 3u"Au |

| Work schedule | 80g±20g |

| Pitch | We make products based on what you need |

| Housing | High temperature resistant plastic |

| Contact resistance of spring pin | 50mOhm Max. |

| Rated voltage | 12V 120V 800V |

| Rated current | 1-30A |

| Mechanical life | 100000 cycles |

| Salt spray test | 48H |

| Packing | PE bag / reel packing |

| Material and coating conform to ROHS and REACH standards | |

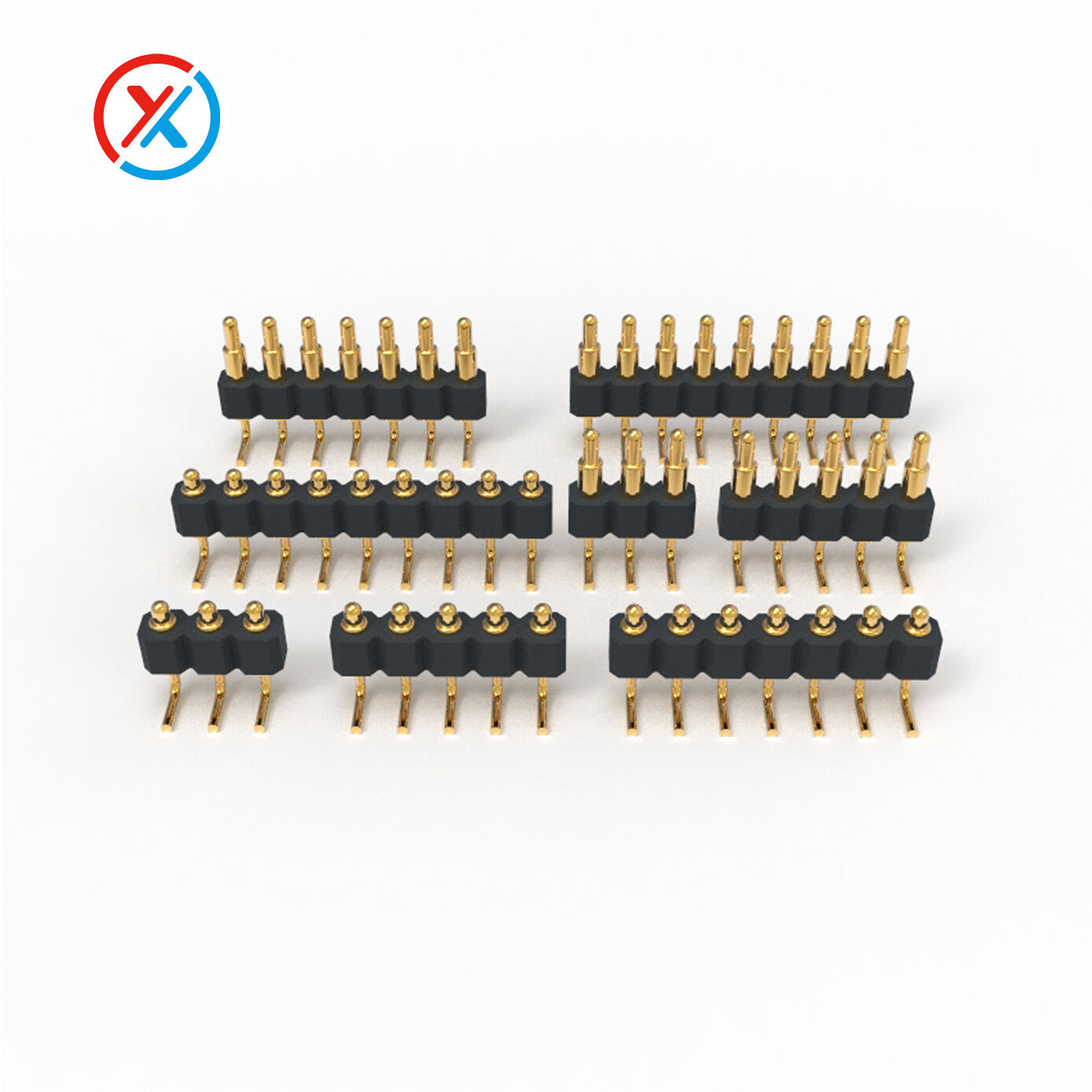

4、Pogo pin connector scheme can be customized according to your requirements.

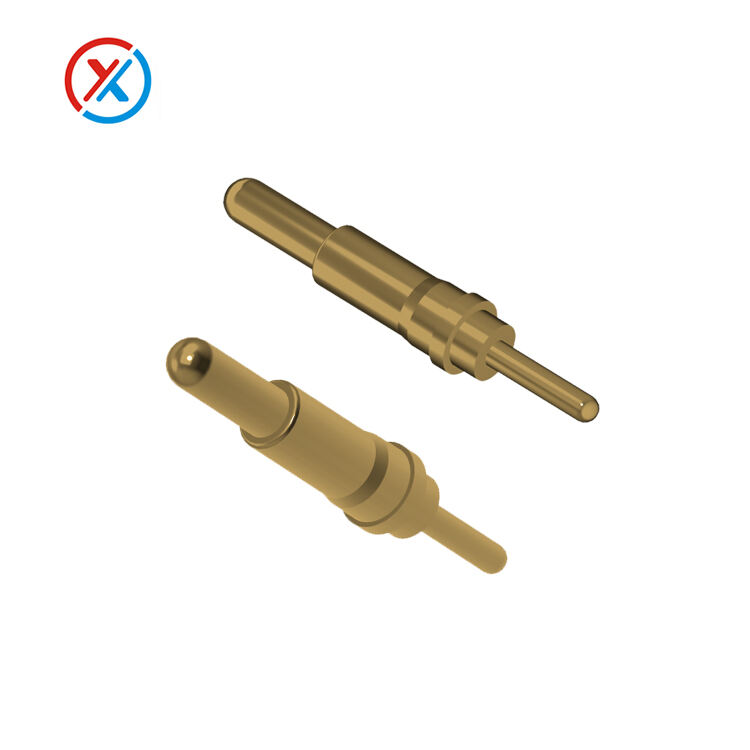

1. Shape structure: SMT,DIP, bend, double pin, welding wire structure, integrated type.

2. Material: C3604 C6801.

3. Elasticity: ≤ 15g.

4. Rated voltage / current: ≤ 120V, ≤ 40A.

5. Connection method: 90 °, 180 °or other angle.

6. Mother end assembly style; DIP, 90 °bending, welding wire, glue wrap molding, etc.

7. Mother end positioning mode: concave and convex groove, sealing ring, clamping lock, positioning ear, positioning column, in-mold injection molding.

Let us be your most reliable supplier!

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

SR

SR

UK

UK

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

SW

SW

GA

GA

CY

CY

IS

IS

BN

BN

BS

BS

NE

NE